Vislumbres da celebração do Dia da Mulher na Atul, Gujarat. Mulheres talentosas, trabalhadoras e felizes em nossos escritórios estão tornando a equipe Atul mais poderosa.

Vislumbres da celebração do Dia da Mulher na Atul, Gujarat. Mulheres talentosas, trabalhadoras e felizes em nossos escritórios estão tornando a equipe Atul mais poderosa.

Recentemente, a empresa Floras da Atul Ltd participou da edição de 2019 da SIAL Oriente Médio, realizada no Abu Dhabi National Exhibition Center. Foi adorável conhecer todos! A Global Food Marketplace (francês: Salon International de l’alimentation, ou SIAL) é uma…

A Empresa crê que o 5S é essencial para alcançar o seu objetivo de desenvolvimento sustentável. Tínhamos iniciado o movimento 5S há poucos anos e temos estado a implementar a iniciativa nas nossas fábricas ao nível básico. Agora, é importante…

Appearance : Dark violet lumps | Colour (Gardner) : > 18 | Methylol content (%) : 12 – 16 | Softening point (oC): 85 – 105

Appearance : Pale yellow lumps | Colour (Gardner) : Max 6 | Methylol content (%) : 14 – 17 | Softening point (oC) : 90 – 100

Appearance : Pale yellow lumps | Colour (Gardner) : Max 4 | Methylol content (%) : 8 – 12 | Melting point, capillary (oC) : 63 – 75 | Softening point (oC) : 65 – 80

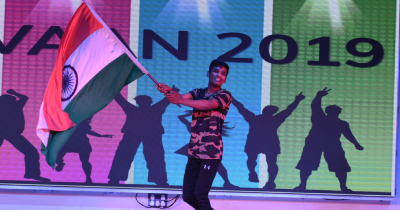

Yuvaan, um programa de entretenimento cheio de diversão e empenhamento para mostrar o talento dos membros da nossa equipa foi organizado na Atul na semana passada. O evento motivou grande participação e união, com uma grande variedade de programas como…

A 42ª Reunião Anual da Administração dos Membros da Atul Ltd realizou-se a 31 de julho de 2019 na Associação de Gestão de Ahmedabad, em Ahmedabad.

O Green Gujarat Awards 2019 foi concedido à Atul Ltd, Ankleshwar no Dia Mundial do Meio Ambiente, 05 de junho de 2019. O prêmio foi recebido por Shri Ganpatbhai Vasava, o Excelentíssimo Ministro do Meio Ambiente e Florestas, Governo de…

A equipe RE participou da competição Kaizen – 5S para Transformação Cultural em Casa, Local de Trabalho e Nova Índia, realizada em 21 e 22 de maio de 2019 em Surat. Eles compartilharam as melhores práticas na implementação do 5S…

An aroma ingredient to enhance pineapple, fruity, sweet and juicy odour, widely used by cosmetics and flavour industry.

An aroma chemical with fruity, wine and banana like odour, used to make flavours and fragrances for personal care industry.

A value added down-stream of ortho Cresol, which plays a key role in the manufacturing of hydrogen peroxide (H2O2). Atul Ltd is the only manufacturer of 2-Methylcyclohexyl acetate, with a captive source of ortho Cresol.

A dye intermediate in organic synthesis.

A Atul organizou seu encontro anual de analistas na semana passada em Mumbai para compartilhar o desempenho da empresa.

Como um pequeno passo à frente em nosso esforço para oferecer educação de qualidade às crianças das aldeias do interior, recentemente, a Fundação Atul doou cinco tablets para uma escola de uma vila em Maan Taluka de Satara, Maharashtra, que…

A 48ª Semana Nacional de Segurança foi comemorada de 04 a 11 de março de 2019. Várias atividades foram organizadas para criar conscientização quanto à segurança industrial entre os membros da família Atul.

Nossa equipe de proteção de culturas participou da Exposição Internacional de Agroquímicos e de Proteção de Culturas da China, em Xangai. As empresas aproveitaram esta oportunidade para conhecerem os clientes e parceiros de negócios para discutirem produtos, serviços e muito…

A Atul participou da Cúpula Global Vibrant Gujarat, 2019. A Cúpula foi inaugurada pelo Excelentíssimo Primeiro Ministro da Índia, Shri Narendra Modi.

A empresa de materiais de desempenho de polímeros participou da ICERP 2019, realizada no Centro de Exposições de Bombaim, em Mumbai. As empresas aproveitaram a oportunidade para compartilharem ideias e conhecimento técnico com nossos clientes.

A Nouryon fechou parceria com a Fundação Atul para fornecer comprimidos de ácido fólico de ferro aos estudantes dos três institutos gerenciados pela Fundação. O objetivo dessa iniciativa é o de melhorar os níveis de hemoglobina dos estudantes (principalmente os…

É com satisfação que compartilhamos que um dos produtos da Atul, o Polygrip HVAC, foi usado para isolar os dutos CA de alta qualidade durante a construção da Estátua da Unidade, que foi revelada hoje por Narendra Modi, Primeiro-Ministro da…

É com satisfação que compartilhamos que um dos produtos da Atul, o Polygrip HVAC, foi usado para isolar os dutos CA de alta qualidade durante a construção da Estátua da Unidade, que foi revelada hoje por Narendra Modi, Primeiro-Ministro da…

Colour (Gardner) : Max 10 | Epoxy value (Eq/kg) : 7.00 – 8.00 | Viscosity @ 150oC (mPa s) : 2,500 – 4,000

Colour (Gardner) : Max 18 | Epoxy value (Eq/kg) : 7.40 – 8.50 | Viscosity @ 150oC (mPa s) : 2,000 – 4,000

Appearance : Clear colourless solution | Formaldehyde content: 37 ± 0.50 | Methanol content: Max 5 | Specific gravity : 1.095 – 1.115 | pH : 2.80 – 5.00

Colour (APHA) : Max 50 | Epoxy value (Eq/kg) : 5.71 – 5.95 | Viscosity @ 25oC (mPa s) : 4,000 – 5,000

A Atul Ltd recebeu o 1º prêmio de Excelência em Gestão de Custos no 15º Prêmio Nacional apresentado pelo Institute of Cost Accountants of India, na categoria Privado – Manufatura – Grande (com faturamento entre Rs 2.500 cr a 5.000…

Appearance : Clear colourless solution | Formaldehyde content: 37 ± 0.50 | Methanol content: Max 5 | Specific gravity : 1.095 – 1.115 | pH : 2.80 – 5.00

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 6.50 – 7.50 | Viscosity @ 50oC (mPa s) : 1,000 – 2,500 | HyCl (%) : Max 0.20

Colour (Gardner) : Max 10 | Epoxy value (Eq/kg) : 7.00 – 8.00 | Viscosity @ 150oC (mPa s) : 2,500 – 4,000 | HyCl (%) : Max 0.10

Colour (Gardner) : Max 18 | Epoxy value (Eq/kg) : 7.40 – 8.50 | Viscosity @ 150oC (mPa s) : 2,000 – 4,000 | HyCl (%) : Max 0.10

As empresas de produtos aromáticos, químicos e farmacêuticos a granel participaram da Chemspec Europe, realizada em Colônia, na Alemanha. As empresas aproveitaram esta oportunidade para conhecerem os clientes e parceiros de negócios para discutirem produtos, serviços e muito mais.

A Atul está comprometida com a conservação do meio ambiente desde a sua criação. Como parte das comemorações do Dia Mundial do Meio Ambiente, foram organizadas várias atividades para divulgar o desenvolvimento sustentável, especialmente a proteção ao meio ambiente. A…

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 10 – 50 | Pot life @ 25oC : 600 min – 700 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 10 – 50 | Pot life @ 25oC : 300 min – 380 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 20 – 100 | Pot life @ 25oC : 80 min – 100 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 20 – 100 | Pot life @ 25oC : 50 min – 60 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 50 – 150 | Pot life @ 25oC : 25 min – 35 hr | Mixing ratio (Parts by weight) : 32

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 150-300 | Pot life @ 25oC : 14 min – 20 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 10 – 150 | Pot life @ 25oC : 10 min – 10 hr | Mixing ratio (Parts by weight) : 32

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 10 – 150 | Pot life @ 25oC : 10 min – 10 hr | Mixing ratio (Parts by weight) : 32

A Atul Ltd organizou seu Encontro Anual de Analistas no dia 04 de maio em Vivanta, no hotel Taj-President, para compartilhar detalhes de desempenho e futuros planos da empresa com gestores de fundos, empresas de gestão de ativos, corretoras, fundos…

A Urmi foi fundada em 1953 pela Atul Ltd com o objetivo de capacitar as mulheres. Ao longo dos anos, as especiarias secas ao sol, trituradas e preparadas de forma tradicional se tornaram a identidade da organização. Cada etapa do…

Lacare® AM 70 is a multi-purpose maintenance spray especially designed to meet the requirements of preventive and corrective maintenance for industrial use, automobiles and common household applications. Lacare® AM 70 is available in the pack size of 45 g, 85…

Lacare® Channel Spray is a superior polymer-based spray used for improving the sliding movement of glass used in car windows. It is especially made to lubricate the rubber beading, plastic and other assemblies used in the sliding windows of automobiles.…

Lacare® Chain Lube is a superior oil based chain lubricant for open chain of bike driven at very high speeds where the chain is exposed to moisture and dusty environments. It is ideal for chains that are standard as well…

LAPOX® TILEGRIP: a high performance, cementitious tile fixing adhesive APPLICATIONS – Fixing floor and wall tiles (internal and external) – Fixing thin bed tiles and medium format tiles – Cladding of vitrified tiles, ceramic tiles, porcelain, mosaic, granite and marble…

Lacare® is a recently introduced range of maintenance products for automobile, industrial and household applications. Channel spray: – Can be applied on rubber channels of glass windows used in cars – Ensures the smooth movement of manual and power window…

Lacare® is a recently introduced range of maintenance products for automobile, industrial and household applications. Chain Lube: – Can be applied on open chains of bikes driven at high speeds + standard chains, O-ring chains, X-ring chains and Z-ring chains…

A Urmi foi fundada pela Atul Ltd em 1953 com o objetivo de capacitar as mulheres, envolvendo-as em atividades objetivas. Ao longo dos anos, especiarias frescas, preparadas de forma tradicional e artesanalmente por mulheres das aldeias vizinhas, tornaram-se a identidade…

Temos o prazer de compartilhar que o Relatório Anual da Atul 2016-17 ganhou recentemente o Silver Shield através de um júri presidido por Shri M. Damodaran, ex-presidente do Conselho de Valores Mobiliários da Índia (SEBI), entre as inscrições recebidas na…

A equipe Atul o convida para visitar a CAC 2018. Esperamos compartilhar mais informações sobre nossos produtos e conhecimento técnico com nossos clientes e parceiros. Será um prazer conhecê-lo.

A empresa Polymers Performance Materials tem prazer em convidá-lo para o JEC WORLD | PAINTINDIA 2018. Mostraremos a nossa variedade de produtos e consideraremos uma oportunidade para compartilhar ideias e conhecimento técnico com nossos clientes. Esperamos que você consiga vir…

Não foi apenas o mundo dos negócios que se beneficiou da visão de Kasturbhai. Ele enriqueceu o tecido educacional, social e cultural da nossa nação com igual distinção. Foi sua firme adesão aos valores que o fizeram verdadeiramente notável. Um…

Lapox Metalam is a two-component modified epoxy system. The product is ideal for applications such as coating and laminating glass, metals, plastic, wood, paper stickers and natural stones. It is available in pack sizes of 1.5 kg and 7.5 kg.

Lapox Metalam is a two-component modified epoxy system. The product is ideal for applications such as coating and laminating glass, metals, plastic, wood, paper stickers and natural stones. It is available in pack sizes of 1.5 kg and 7.5 kg.

Lapox Granito is a two-component modified epoxy based system. The product is ideal for applications such as casting of decorative parts and table top. It is available in pack sizes of 1.25 kg, 5 kg and 10 kg.

Representantes de empresas aromáticas, químicos e farmacêuticos a granel participaram da CPhI India, Mumbai. Eles procuraram pelos clientes e parceiros para discutirem as soluções e produtos de alta qualidade para atenderem às suas necessidades exclusivas de fabricação.

Fundada pela Atul Ltd em 1953, a Urmi trabalha para empoderar as mulheres. Especiarias frescas e preparadas de forma tradicional são a identidade da organização. As mulheres das aldeias vizinhas estão envolvidas na secagem, esmagamento, mistura e embalagem dessas especiarias.…

No dia promissor de Laabh Panchami de 2017, a Atul inaugurou sua nova usina – o maior projeto da história da empresa. As unidades de caldeiras, usinas de carvão, turbinas e manuseio cinzas da fábrica são operadas pela DCS e…

On October 25, 2017 on the auspicious occasion of Laabh Pancham (Gyaan Panchami), our Colors Business inaugurated its new Analytical laboratory at Atul. Well-equipped with the latest spectroscopic instruments, this state-of-the-art facility will enhance the quality assurance of dyes and…

Em 25 de outubro de 2017, na promissora ocasião de Laabh Pancham (Gyaan Panchami), nossa Colors Business inaugurou seu novo laboratório analítico em Atul. Bem equipada com os mais recentes instrumentos espectroscópicos, esta instalação de última geração aumentará a garantia…

Atul will be participating at AgroChemEx Shanghai, 2017. AgroChemEx is an annual agrochemical symposium and exhibition organised by the China Crop Protection Industry Association. It provides a valuable platform for the exchange of information and business development opportunities by attracting…

Efficax, launched by Atul, is a super spreader surfactant for agriculture use with high penetration. Key features of this product are outlined below. 100% pure trisiloxane increases efficacy of crop care chemicals used improves spraying efficiency safe to use with…

A 21ª Associação de Escolas para o Certificado de Escola Indiana (ASISC) – Encontro Aquático Nacional, foi realizada entre 30 de setembro e 01º de outubro de 2017. O evento foi realizado pela quarta vez por Atul Vidyalaya sob o…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (m Pas) : 700 – 1,200 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (m Pas) : 700 – 1,200 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90

Junto com sua equipe, Sadhguru está viajando de Kanyakumari para o Himalaia, como parte do Rali pelos Rios, uma iniciativa para divulgar o esgotamento dos rios e uma necessidade urgente de salvá-los. Atul, localizada às margens do Rio Par, foi…

Mixing ratio (Parts by weight) : 100 : 38 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 110 – 160 | Glass transition temperature (Tg) (o) : 115 – 130

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 8.15 – 9.50 | Viscosity @ 25oC (mPa s) : 100 – 200

Epoxy value (Eq/kg) : 2.15 – 2.22 | Viscosity @ 25oC (mPa s) : 160 – 190 | Softening point (oC) : 65 – 75 |

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio (Parts by weight) : 100 : 70 | Glass transition temperature (Tg) (oC) : 100 – 110 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 80 : 0 – 8 | Glass transition temperature (Tg) (oC) : 105 – 115 | Thermal class :…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 75 – 85

Appearance : Yellow to brown liquid | Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 100 – 300 | Amine value (mg KOH/g) : 628 – 634 | Mixing ratio (Parts by weight) : 24

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 5 – 15 | Pot life @ 25oC (hours) : 7 – 9 | Mixing ratio (Parts by weight) : 32

2017 marks the 70th anniversary of Atul Ltd. The history of the Company is closely linked to that of independent India: both started their journey in 1947 and endeavour to consistently improve over the years. In light of this, Polymers…

Polymers Retail is launching a new range of maintenance products under the brand Lacare for automobile, industrial and household applications. The upcoming product portfolio for this maintenance range is as follows: Generic name Application Multi-purpose maintenance spray Penetrates rust and…

Polymers Retail had a pilot launch of its retail module from April-June 2017 in Valsad, Pardi and Udwada. While it has been challenging for the Business to move from a no presence zone to a significant presence zone, the experience…

Polymers Performance Materials participated in ICERP 2017 in Mumbai. The exhibition was held on 10 – 12 January 2017. It gave us an opportunity to personally meet and discuss with the various personnel and decision makers of composites industry.

Atul Ltd received a certificate of merit for its greening the desert project by Flame Awards Asia, 2016

These fresh Barhee dates are from Atul’s farms in the beautiful Thar desert in Rajasthan and farmer fields in various parts of India, cultivated with Atul’s tissue culture raised date palms.

Colors Business launched an innovative mobile application for effective customer service and was conferred with the Customer Excellence award.

Dr GVG Rao, President, Colors Business, inaugurated new machinery at the Technical Services (TS) laboratory, Atul. The TS laboratory focuses on customer support activities, particularly textile dyeing and printing application techniques.

A representative from Colors Business participated in and conducted a technical seminar on ‘Selection, Evaluation, Application and Disposal of Dyes and Chemicals’ in Ethiopia. The seminar was organised by the Ethiopian Textile Industry Development Institute in twinning partnership with the…

A AkzoNobel e a Atul anunciaram sua intenção de investir juntas na produção de ácido monocloroacético (MCA) na Índia. Isso incluirá a instalação de uma fábrica MCA de classe mundial no primeiro local de manufatura da Atul, localizada em Valsad…

Por ocasião do festival Ambedkar Jayanti, o Primeiro-ministro Narendra Modi, sob o comando de Digi Dhan Vyapar Yojana, de Niti Aayog, declarou que o Município de Atul Ltd, em Valsad, está entre os setenta e cinco ‘municípios sem dinheiro’ da…

As tâmaras frescas de Barhee são das fazendas de Atul no belo deserto de Thar, no Rajastão, e das plantações de várias partes da Índia, cultivadas com as palmeiras de tâmaras de cultura de tecidos de Atul.

Em 2016-17, a Fundação Atul organizou exames oftalmológicos e otorrinolaringológicos, beneficiando 3.103 pacientes em 10 aldeias, sendo que 129 foram operados por catarata e 551 receberam óculos.

A bio-stimulant derived from seaweed extract (Ascophyllum nodusum). The product is used as a plant growth stimulant, enhancing plant vigour at critical stages and improving crop productivity.

A silicone based surfactant used as a tank mix with and herbicides, insecticides and fungicides to improve its bio-efficacy.

A selective pre-emergence herbicide used to control most grasses and some broad-leaved weeds in various crops.

A selective pre-emergence herbicide used to control most grasses and some broad-leaved weeds in various crops.

A selective pre and early post-emergence herbicide of the Triazine group used to control a wide range of grasses and broad-leaved weeds in maize and sugarcane.

A broad spectrum systemic post-emergence herbicide used to control grassy weeds such as Echinochloa spp, sedges and broad-leaved weeds in paddy.

A selective, pre-emergence herbicide used to control most grasses and some broad-leaved weeds in transplanted paddy.

A non-selective, post-emergence contact herbicide used to control annual grasses and broad-leaved weeds in tea, row crops and non-crop areas.

A systemic insecticide with protective and curative action used to control blast in paddy.

A sulphur based fertiliser for soil application used to overcome sulphur deficiencies and nutrition stress in plants and the soil.

An inorganic contact fungicide with protective action and acaricidal activity. The product is recommended for controlling powdery mildews in various crops.

A broad spectrum systemic fungicide of the Benzimidazole group used to control a range of diseases in various crops, with its protective and curative action.

A broad spectrum contact and protective fungicide and bactericide used to control wide range of fungal diseases in various crops.

A systemic insecticide of the Neonicotinoid and Phenylpyrazole group with contact and stomach action. The product is used to control chewing and sucking insect pests.

A broad spectrum insecticide and acaricide of the Organophosphorus group used to control a range of chewing and sucking insects in various crops.

A broad spectrum insecticide | miticide of the Synthetic pyrethroids group with contact and stomach action. The product is effective against a broad range of lepidopteran pests, sucking pests, mites and termites in various crops.

A non-systemic insecticide of Organophosphorus and Synthetic pyrethroids group with contact and stomach action. The product is used to control chewing and sucking insect pests.

One-component, solvent free, nearly instant setting adhesive. The product is ideal for applications such as bonding of marble, glass, metal, plastic, wood, sun board and flex and filling gaps in PVC doors. Lapox Ultraquick is available in the pack size…

A systemic fungicide that is used to control scab in apple, tikka leaf spot in groundnut, powdery mildew in mango and blast and sheath blight in rice.

A systemic fungicide of the Triazole group used to control fungal diseases. The product finds an application in wood preservation.

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 25 – 35

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : Thixotropic | Pot life @ 25oC (minutes) : 3 – 7

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 200 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) oC : 105 –…

Mixing ratio (Parts by weight) : 100 : 40 | Mix viscosity @ 25oC (mPa s) : Thixotropic | Pot life @ 25oC (minutes) : 35 – 45

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 100 – 110

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 6,000 – 8,000 | Pot life @ 25oC (minutes) : 15 – 300

Mixing ratio (Parts by weight) : 100 : 65 | Mix viscosity @ 25oC (mPa s) : 8,000 – 10,000 | Pot life @ 25oC (minutes) : 15 – 330

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 43 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 30 – 35

Mixing ratio (Parts by weight) : 100 : 55 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 45 – 60

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : 35 – 330

Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 25 – 35

Mix viscosity @ 25oC (mPa s) : 600 – 1,000 | Pot life @ 25oC (minutes) : 130 – 150

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,500 – 4,500 | Pot life @ 25oC (minutes) : 110 – 130

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,500 | Pot life @ 25oC (minutes) : 60 – 80

Mixing ratio (Parts by weight) : 100 : 66 | Mix viscosity @ 25oC (mPa s) : 4,500 – 5,500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 50,000 – 1,00,000 | Pot life @ 25oC (minutes) : 35 – 50

Mixing ratio (Parts by weight) : 100 : 80 | Mix viscosity @ 25oC (mPa s) : 75,000 – 1,25,000 | Pot life @ 25oC (minutes) : 8 – 10

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 2,500 – 3,000 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 190 – 220

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 120 – 180 | Glass transition temperature (Tg) (oC) : 130 – 140

Mixing ratio (Parts by weight) : 100 : 20 | Mix viscosity @ 25oC (mPa s) : Paste (colourless) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 95 – 115

Mixing ratio (Parts by weight) : 100 : 10 | Mix viscosity @ 25oC (mPa s) : Paste (blue) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 6 | Mix viscosity @ 25oC (mPa s) : Paste (grey) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 85 – 95

Mixing ratio (Parts by weight) : 100 : 14 | Mix viscosity @ 25oC (mPa s) : Paste (white) | Pot life @ 25oC (minutes) : 25 – 30 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 38 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 110 – 160 | Glass transition temperature (Tg) (oC) : 115 – 130

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 111,000 – 13,000

A cost effective substitute for cresylic acid and phenol.

An economical trichromatic navy dye with good dischargeability. The product is used to develop medium to dark shades.

A deep red dye used for scarlet, dark red, brown and burgundy shades.

A red dye with high tinctorial strength and excellent build-up properties. The product is used to develop medium to dark shades.

A golden yellow dye with high tinctorial strength used to develop deep shades with good all round fastness properties.

A basic trichromatic golden yellow dye with good dischargeability.

A blue dye with good light fastness properties used for pale to medium shades.

A red dye with good light fastness properties used for pale to medium shades.

A yellow dye with good light fastness properties used for pale to medium shades.

An economical navy dye with good build-up properties.

A black dye used to develop black to grey shades. The product has good light fastness properties.

A turquoise dye with good build-up properties.

A turquoise dye with good build-up properties.

A brilliant reddish blue dye used to develop bright royal blue shades.

A trichromatic blue dye with good fastness properties. The product has good dischargeability.

A bright violet dye used for various shades of violet.

An economical bluish red dye used for medium and dark shades.

An economical trichromatic red dye with high tinctorial strength.

A bright orange dye used for orange and scarlet shades.

An economical golden yellow dye used in trichromatic combinations.

A bright yellow dye used in tertiary combinations with good light fastness properties.

A yellow dye with all round fastness properties.

An ideal grey component with excellent performance in Exhaust and Continuous dyeing applications by Soft flow and Pad Dry Pad steam techniques. The product has good all round fastness properties. It is available in Microperle and Micro disperse varieties.

A navy dye with excellent build-up properties used for coloration of workwear and institutional wear. The product is used in combination with Yellow 3R and Jade Green XBN for Exhaust application. It shows minimum shade change when used with flame…

A systemic fungicide with protective and curative action used to control broad spectrum fungal diseases in various field crops and fruits.

A selective and systemic post-emergence herbicide readily absorbed by leaves. The product is used to control annual and perennial broad-leaved weeds in a range of crops.

A high purity grade of para Cresol for niche applications.

A starting ingredient in most versatile phenolic group antioxidants.

A naturally sourced aroma ingredient with a musk-like profile.

A key ingredient in specialty fragrance formulations.

An intermediate widely used by the Pharmaceuticals and Crop Protection Chemicals industry.

An aroma ingredient with sweet, floral, fennel and basil-like, mildly fruity odour. The product finds a major application in oral care products, flavours and fragrances.

A key building block for Dextromethorphan, a widely used formulation to treat cough and cold.

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 600 – 1,000 | Pot life @ 25oC (minutes) : 130 – 150

Mixing ratio (Parts by weight) : 100 : 66 | Mix viscosity @ 25oC (mPa s) : 4,500 – 5,500 | Pot life @ 25oC (minutes) : 40 – 50

Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 7,000 – 11,000 | Amine value (mg KOH/g) : 400 – 450 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight)…

Type of system : Pre-filled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 26 | Glass transition temperature (Tg) (oC) : 70 – 80 | Thermal class : F

Type of system : Pre-filled | Nature : Cold cure / Indoor | Mixing ratio (Parts by weight) : 100 : 25 | Glass transition temperature (Tg) (oC) : 60 – 70 | Thermal class : B

Type of system : Unfilled | Nature : Hot cure Indoor | Voltage class : MV / HV | Mixing ratio (parts by weight) : 100 : 15 | Glass transition temperature (Tg) (oC) : 80 – 90 | Thermal…

Appearance : Yellow liquid | Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 1,000 – 2,500 | Amine value (Eq/kg) : 8.00 – 9.00 | Mixing ratio (Parts by weight) : 34

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (Parts by weight) : 100 : 100 : 0.0 – 0.2 | Glass transition temperature (Tg) (oC) : 90 – 100 | Thermal class :…

Colour (Gardner) : Max 10 | Epoxy value (Eq/kg) : 2.20 – 2.60 | Viscosity @ 25oC (mPa s) : 20 – 50 | HyCl (%) : Max 1.00

Colour (Gardner) : Max 13 | Epoxy value (Eq/kg) : 1.80 – 2.40 | Viscosity @ 25oC (mPa s) : 40 – 70 | HyCl (%) : Max 1.00

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.10 – 4.50 | Viscosity @ 25oC (mPa s) : 20 – 35 | HyCl (%) : Max 0.20

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.90 – 6.30 | Viscosity @ 25oC (mPa s) : 6 – 8 | HyCl (%) : Max 0.20

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.30 – 6.00 | Viscosity @ 25oC (mPa s) : 6 – 8 | HyCl (%) : Max 0.20

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (Parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoo | Mixing ratio (parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 25 | Glass transition temperature (Tg) (oC) : 122 – 132 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC) : 90 – 105 | Thermal class : H

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC): 105 – 125 | Thermal class : H

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 100 : 0.5 – 1.5 : 0 – 20 | Glass transition temperature (Tg) (oC): 85 – 95 | Thermal class :…

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC) : 75 – 85 | Thermal class : F

Colour (Gardner) : Max 6 | Epoxy value (Eq/kg) : 1.54 – 2.00 | Viscosity @ 25oC (mPa s) : 250 – 500

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 80 : 0.5 – 2.0 | Glass transition temperature (Tg) (oC) : 75 – 85 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio (Parts by weight) : 100 : 90 | Glass transition temperature (Tg) (oC): 100 – 110 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 90 : 0.5 – 2.0 | Mix viscosity : 1,000/80 | Glass transition temperature (Tg) (oC): 100 – 110 | Thermal class…

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 7.00 – 8.00 | Viscosity @ 25oC (mPa s) : 100 – 200 | HyCl (%) : Max 0.15

Type of system : Pre-filled | Nature : Hot cure Indoor | Mixing ratio (parts by weight) : 100 : 100 | Glass transition temperature (Tg) (oC) : 110 – 120 | Thermal class : H

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.90 – 8.00 | Viscosity @ 25oC (mPa s) : 12 – 18 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 2.90 – 3.20 | Viscosity @ 25oC (mPa s) : 40 – 90 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.20 – 6.80 | Viscosity @ 25oC (mPa s) : 15 – 30 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 7.00 – 7.80 | Viscosity @ 25oC (mPa s) : 10 – 22 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.20 – 7.30 | Viscosity @ 25oC (mPa s) : Max 2 | HyCl (%) : Max 0.10

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 3.35 – 3.70 | Viscosity @ 25oC (mPa s) : 4 – 12 | HyCl (%) : Max 0.10

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.50 – 6.30 | Viscosity @ 25oC (mPa s) : 500 – 1,100

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.10 – 5.40 | Viscosity @ 25oC (mPa s) : 860 – 960

Mixing ratio (Parts by weight) : 100 : 40 | Mix viscosity @ 25oC (mPa s) : 50,000 – 1,00,000 | Pot life @ 25oC (minutes) : 20 – 25

Mixing ratio (Parts by weight) : 100 : 65 | Mix viscosity @ 25oC (mPa s) : 8,000 – 10,000 | Pot life @ 25oC (minutes) : 15 – 330

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.40 – 5.90 | Viscosity @ 25oC (mPa s) : 1,000 – 1,500

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.40 – 5.90 | Viscosity @ 25oC (mPa s) : 1,700 – 2,500

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 100 – 110

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 6,000 – 8,000 | Pot life @ 25oC (minutes) : 15 – 300

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 25 – 35

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) :100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 43 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 30 – 35

Mixing ratio (Parts by weight) : 100 : 55 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 45 – 60

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : 35 – 330

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,500 – 4,500 | Pot life @ 25oC (minutes) : 110 – 130

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,500 | Pot life @ 25oC (minutes) : 60 – 80

Chemistry : 3,3′-Diaminodiphenyl sulfone | Appearance : White to brownish white powder | Melting point (oC) : 167 – 175

Chemistry : 4,4′-Diaminodiphenyl sulfone Micronised | Appearance : White to off-white powder | Melting point (oC) : 176 – 180

Chemistry : 4,4′-Diaminodiphenyl sulfone Free Flow | Appearance : White to off-white powder | Melting point (oC) : 176 – 185

Chemistry : 4,4′-Diaminodiphenyl sulfone | Appearance : White to off-white powder | Melting point (oC) : 176 – 185

Chemistry : 4,4′-Diaminodiphenyl methane | Appearance : Viscous brownish liquid | Viscosity @ 60oC (mPa s) : 1,400 – 2,000

Appearance : Light yellow to brown liquid | Viscosity @ 25oC (mPa s) : 100 – 300

Chemistry : 4,4′-Diaminodicyclohexyl methane | Appearance : Colourless transparent liquid | Melting point (oC) : 35 – 37

Chemistry : 3,3’-Dimethyl-4,4’-diaminodicyclohexyl methane | Viscosity @ 25oC (mPa s) : 100 – 140

Colour (Gardner) : Yellow powder | Melting point (oC) : 155 – 158

Colour (Gardner) : Yellow solid | Viscosity @ 125oC (mPa s) : 50 – 500

Colour (Gardner) : Yellowish liquid | Solid content (%) : 74 – 76 | Viscosity @ 25oC (mPa s) : 100 – 400

Colour (Gardner) : Yellow solid | Viscosity @ 100oC (mPa s) : 1,000 – 7,000 | Softening point (oC) : 60 – 80

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 4.17 – 4.44 | Viscosity @ 85oC (mPa s) : 1,000 – 1,500

Epoxy value (Eq/kg) : 9.80 – 10.6 | Viscosity @ 25oC (mPa s) : 1,500 – 4,800

Epoxy value (Eq/kg) : 9.10 – 9.80 | Viscosity @ 25oC (mPa s) : 7,000 – 13,000

Epoxy value (Eq/kg) : 9.40 – 10.50 | Viscosity @ 25oC (mPa s) : 550 – 850

Epoxy value (Eq/kg) : 8.70 – 9.50 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000

Colour (Gardner) : Max 13 | Epoxy value (Eq/kg) : 5.88 – 6.66 | Viscosity @ 150oC (mPa s) : 30 – 55

Colour (Gardner) : Max 7 | Epoxy value (Eq/kg) : 7.52 – 8.47 | Viscosity @ 25oC (mPa s) : 7,000 – 12,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 8.55 – 9.00 | Viscosity @ 50oC (mPa s) : 3,000 – 6,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 7,000-19,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 17,000-19,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 13,000-15,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 10,000 – 12,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 7,000 – 11,000

Colour (Gardner) : Max 4 | Epoxy value (Eq/kg) : 5.12 – 6.10 | Viscosity @ 50oC (mPa s) : 100 – 350

Colour (Gardner) : Max 3 | Epoxy value (Eq/kg) : 5.59 – 5.81 | Viscosity @ 52oC (mPa s) : 1,100 – 1,700

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 6.50 – 7.50 | Viscosity @ 50oC (mPa s) : 1,000 – 2,500 | Hycl : Max 0.20

Colour (APHA) : Max 50 | Epoxy value (Eq/kg) : 5.71 – 5.95 | Viscosity @ 25oC (mPa s) : 4,000 – 5,000

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.26 – 5.55 | Viscosity @ 25oC (mPa s) : 9,000 – 12,000

Epoxy value (Eq/kg) : 0.53 – 0.59 | Viscosity @ 25oC (mPa s) : 1,800 – 2,600 | Softening point (oC) : 110 – 120

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 15,000 – 35,000 | Amine value (mg KOH/g) : 290 – 325 | Pot life @ 25oC (minutes) : 40 – 85 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Amine value (mg KOH/g) : 490 – 550 | Pot life @ 25oC (minutes) : 30 – 55 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000 | Amine value (mg KOH/g) : 300 – 350 | Pot life @ 25oC (minutes) : 50 – 65 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 3 | Viscosity @ 25oC (mPa s) : 40 – 60 | Amine value (mg KOH/g) : 320 – 340 | Pot life @ 25oC (minutes) : 25 – 40 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 10 – 20 | Pot life @ 25oC (minutes) : 90 – 120 | Mixing ratio (Parts by weight) : 23

Colour : Max 2 | Viscosity @ 25oC (mPa s) : 1,500 – 2,000 | Amine value (Eq/kg) : 165 – 210 | Pot life @ 25oC (hours) : 4 – 6 | Mixing ratio (Parts by weight) : 30…

Colour (Gardner) : Clear liquid | Viscosity @ 25oC (mPa s) : 850 – 1,200 | Mixing ratio (Parts by weight) : 100 (with resin ARL-148)

Colour (Gardner) : Black | Viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : Min 20 | Mixing ratio (Parts by weight) : 100 (with resin ARB – 28)

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 2,900 – 3,600 | Amine value (mg KOH/g) : 398 – 415 | Pot life @ 25oC (minutes) : 15 – 30 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 200 – 300 | Amine value (Eq/kg) : 17.00 – 17.80 | Pot life @ 25oC (minutes) : 25 – 35 | Mixing ratio (Parts by weight) :…

Colour (Gardner) : Max 5 | Viscosity @ 25oC (mPa s) : Max 10 | Pot life @ 25oC (minutes) : 20 – 25 | Mixing ratio (Parts by weight) : 10 – 12

Colour (Gardner) : Max 3 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight) : 10 – 12

Colour (Gardner) : Max 5 | Viscosity @ 25oC (mPa s) : 100 – 550 | Amine value (mg KOH/g) : 500 – 1,000 | Pot life @ 25oC (minutes) : 5 – 30 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 500 – 1,000 | Amine value (mg KOH/g) : 650 – 750 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 5 – 10 | Amine value (mg KOH/g) : 680 – 720 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 30 – 100 | Amine value (mg KOH/g) : 290 – 320 | Pot life @ 25oC (minutes) : 100 – 125 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 50 – 60 | Pot life @ 25oC (minutes) : 35 – 50 | Mixing ratio (Parts by weight) : 15

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 5,000 – 7,500 | Amine value (Eq/kg) : 4.40 – 5.10 | Mixing ratio (Parts by weight) : 60

Mixing ratio (Parts by weight) : 100 : 15 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : 85 – 95 | Glass transition temperature (Tg) (oC) : 95 – 105

Mixing ratio (Parts by weight) : 100 : 15 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : 20 – 25 | Glass transition temperature (Tg) (oC) : 95 – 105

Colour (APHA) : Max 100 | Epoxy value (Eq/kg) : 4.16 – 4.54 | Viscosity @ 25oC (mPa s) : 2,000 – 4,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 6.00 – 6.40 | Viscosity @ 25oC (mPa s) : 1,200 – 1,600

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.30 | Viscosity @ 25oC (mPa s) : 5,000 – 7,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.10 | Viscosity @ 25oC (mPa s) : 3,300 – 4,100

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.10 | Viscosity @ 25oC (mPa s) : 2,000 – 3,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.70 – 6.30 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000

Epoxy value (Eq/kg) : 1.07 – 1.16 | Viscosity @ 25oC (mPa s) : 620 – 900 | Softening point (oC) : 100 – 110

Epoxy value (Eq/kg) : 1.25 – 1.40 | Viscosity @ 25oC (mPa s) : 500 – 700 | Softening point (oC) : 95 – 101

Mixing ratio (Parts by weight) : 100 : 3-6 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 165 – 180

Mixing ratio (Parts by weight) : 100 : 32-40 : 1-3 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 170 – 185

Mixing ratio (Parts by weight) : 100 : 64 : 1-3 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 34 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) oC : 145 – 155

Mixing ratio (Parts by weight) : 100 : 100 : 1-3 | Mix viscosity @ 25oC (mPa s) : 400 – 700 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 95 –…

Mixing ratio (Parts by weight) : 100 : 27 | Mix viscosity @ 50oC (mPa s) : 3,000 – 5,000 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 150 – 160

Mixing ratio (Parts by weight) : 100 : 95 : 0.5-2.0 | Mix viscosity @ 25oC (mPa s) : 1,900 – 2,100 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 165 –…

Mixing ratio (Parts by weight) : 100 : 90 | Mix viscosity @ 25oC (mPa s) : 300 – 600 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 115 – 125

Mixing ratio (Parts by weight) : 100 : 90 : 1-3 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 115 –…

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 200 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 105 –…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 400 – 700 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 1,200 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 1,200 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 800 | Pot life @ 25oC (minutes) : 7 – 9 hr | Glass transition temperature (Tg) oC : 85 –…

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 1,200 – 1,500 | Pot life @ 25oC (minutes) : 120 – 150 | Glass transition temperature (Tg) oC : 55 – 65

Mixing ratio (Parts by weight) : 100:32 | Mix viscosity @ 25oC (mPa s) : 600 – 800 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 20 | Mix viscosity @ 25oC (mPa s) : Paste (colourless) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 95 – 115

Mixing ratio (Parts by weight) : 100 : 10 | Mix viscosity @ 25oC (mPa s) : Paste (blue) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 14 | Mix viscosity @ 25oC (mPa s) : Paste (white) | Pot life @ 25oC (minutes) : 25 – 30 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 24 | Mix viscosity @ 25oC (mPa s) : 250 – 400 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 125 – 135

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 3.57 – 4.45 | Viscosity @ 25oC (mPa s) : 450 – 800

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 800 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 75 – 85

Epoxy value (Eq/kg) : 1.08 – 1.18 | Viscosity @ 25oC (mPa s) : 430 – 550 | Softening point (oC) : 90 – 100

Epoxy value (Eq/kg) : 1.23 – 1.33 | Viscosity @ 25oC (mPa s) : 480 – 580 | Softening point (oC) : 80 – 90

Epoxy value (Eq/kg) : 1.33 – 1.40 | Viscosity @ 25oC (mPa s) : 500 – 600 | Softening point (oC) : 95 – 101

Mixing ratio (Parts by weight) : 100 : 5 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 15 : 2 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 155 – 165

Mixing ratio (Parts by weight) : 100 : 32 : 1-3 | Pot life @ 25oC (weeks) : 2 – 3 | Glass transition temperature (Tg) (oC) : 130 – 140

Mixing ratio (Parts by weight) : 100 : 23 : 0.5-3.0 | Pot life @ 25oC (weeks) : 2 – 3 | Glass transition temperature (Tg) (oC) : 130 – 140

Epoxy value (Eq/kg) : 1.25 – 1.35 | Viscosity @ 150oC (mPa s) : 4,500 – 6,500 | Glass transition temperature (Tg) (oC) : 55

Mixing ratio (Parts by weight) : 100 : 35 : 1-3 | Pot life @ 25oC (weeks) : 6 – 8 weeks | Glass transition temperature (Tg) (oC) : 150 – 160

Epoxy value (Eq/kg) : 1.42 – 1.53 | Viscosity @ 25oC (mPa s) : 375 – 475 | Softening point (oC) : 80 – 90

Appearance : Clear yellow liquid | Colour (Gardner) : Max 6 | Viscosity @ 25oC (mPa s) : 150 – 300 | Amine value (mg KOH/g) : 580 – 635

Mixing ratio (Parts by weight) : 100 : 27 | Pot life @ 25oC (hours) : > 4 | Glass transition temperature (Tg) (oC) : 150 – 160

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 300 – 600 | Amine value (mg KOH/g) : 260 – 310 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 150 – 300 | Amine value (mg KOH/g) : 335 – 375 | Pot life @ 25oC (minutes) : 25 – 40 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 50 – 150 | Amine value (mg KOH/g) : 340 – 390 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 600 – 900 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 130 –…

Colour (Gardner) : Max 2 | Amine value (mg KOH/g) : 330 – 360 | Pot life @ 25oC (minutes) : 20 – 50 | Mixing ratio (Parts by weight) : 45

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 1,500 – 2,500 | Pot life @ 25oC (minutes) : 300 – 350 | Glass transition temperature (Tg) (oC) : 130 – 140

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 400 – 600 | Amine value (mg KOH/g) : 250 – 300 | Pot life @ 25oC (minutes) : 30 – 45 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 12 | Viscosity @ 25oC (mPa s) : 1,000 – 2,000 | Amine value (mg KOH/g) : 280 – 300 | Pot life @ 25oC (minutes) : 46 – 65 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 10 | Viscosity @ 25oC (mPa s) : 2,500 – 5,500 | Amine value (mg KOH/g) : 202 – 225 | Pot life @ 25oC (minutes) : 80 – 100 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 500 – 1,000 | Amine value (mg KOH/g) : 425 – 450 | Pot life @ 25oC (minutes) : 120 – 130 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 9 | Viscosity @ 25oC (mPa s) : 12,000 – 18,000 | Amine value (mg KOH/g) : 350 – 400 | Pot life @ 25oC (minutes) : 60 – 80 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 9 | Viscosity @ 25oC (mPa s) : 45,000 – 60,000 | Amine value (mg KOH/g) : 290 – 320 | Pot life @ 25oC (minutes) : 110 – 130 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 6 | Mix viscosity @ 25oC (mPa s) : Paste (grey) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 85 – 95

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 2,500 – 3,000 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 190 – 220

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 100 – 110

Colour (Gardner) : Max 9 | Viscosity @ 40oC (mPa s) : 50,000 – 75,000 | Amine value (mg KOH/g) : 210 – 230 | Mixing ratio (Parts by weight) : 100 – 125

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 700 – 900 | Amine value (Eq/kg) : 4.70 – 5.00 | Mixing ratio (Parts by weight) : 60

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 120 – 180 | Glass transition temperature (Tg) (oC) : 130 – 140

Appearance : Dark brown liquid | Colour (Gardner) : Max 16 | Viscosity @ 25oC (mPa s) : 15,000 – 21,000 | Amine value (Eq/kg) : 4.40 – 4.80 | Mixing ratio (Parts by weight) : 60

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 3,800 – 5,800 | Amine value (Eq/kg) : 4.70 – 5.10 | Mixing ratio (Parts by weight) : 60

Epoxy value (Eq/kg) : Max 0.08 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000 | Non-volatile content (%) : 49 – 51 (160oC/2h)

Epoxy value (Eq/kg) : 1.80 – 2.20 | Viscosity @ 25oC (mPa s) : 14,000 – 20,000 | Non-volatile content (%) : 74 – 76 (150oC/2h)

Epoxy value (Eq/kg) : 1.90 – 2.20 | Viscosity @ 25oC (mPa s) : 9,000 – 13,000 | Non-volatile content (%) : 74 – 76 (150oC/2h)

Epoxy value (Eq/kg) : 3.10 – 3.40 | Viscosity @ 25oC (mPa s) : 600 – 850 | Non-volatile content (%) : 79 – 81 (150oC/1h)

Colour (Gardner) : Max 3 | Epoxy value (Eq/kg) : 5.50 – 6.00 | Viscosity @ 25oC (mPa s) : 25,000 – 35,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.40 – 4.60 | Viscosity @ 25oC (mPa s) : 800 – 1,500 | Non-volatile content (%) :79 – 81 (150oC/1h)

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.40 – 4.60 | Viscosity @ 25oC (mPa s) : 150 – 350 | Non-volatile content (%): 79 – 81 (105oC/2h)

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 22 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 140 – 155

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 170 – 200

Mixing ratio (Parts by weight) : 100 : 35 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 300 – 350 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 350 – 450 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90