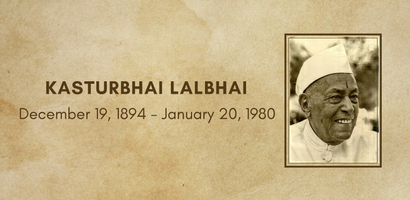

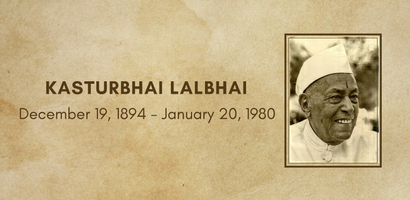

不仅商界受益于Kasturbhai的远见卓识;Kasturbhai同样出色地丰富了我们国家的教育、社会和文化结构。他真正的杰出源自其坚定不移的价值观。Kasturbhai既是一名精明的远见卓识者和先驱,也是一名敬业的人道主义者和杰出的领袖,他的生活每天都在激励着我们。 我们钦佩他的远见卓识,恭敬地低下头。

不仅商界受益于Kasturbhai的远见卓识;Kasturbhai同样出色地丰富了我们国家的教育、社会和文化结构。他真正的杰出源自其坚定不移的价值观。Kasturbhai既是一名精明的远见卓识者和先驱,也是一名敬业的人道主义者和杰出的领袖,他的生活每天都在激励着我们。 我们钦佩他的远见卓识,恭敬地低下头。

Lapox Metalam is a two-component modified epoxy system. The product is ideal for applications such as coating and laminating glass, metals, plastic, wood, paper stickers and natural stones. It is available in pack sizes of 1.5 kg and 7.5 kg.

Lapox Metalam is a two-component modified epoxy system. The product is ideal for applications such as coating and laminating glass, metals, plastic, wood, paper stickers and natural stones. It is available in pack sizes of 1.5 kg and 7.5 kg.

Lapox Granito is a two-component modified epoxy based system. The product is ideal for applications such as casting of decorative parts and table top. It is available in pack sizes of 1.25 kg, 5 kg and 10 kg.

1953年,阿图成立了Urmi,后者致力于赋予妇女权利。新鲜、传统制作的香料是该组织的标志。周围村庄的妇女负责干燥、捣碎、混合、包装这些香料。捣碎会形成独特的香味、外观和风味,产品因此与通常可获得的产品不同。其主要产品包括辣椒粉(轻辣、中辣、特辣)、芫荽孜然粉、辛辣香料粉、泡菜香料粉、香料茶、姜黄粉。 凭借其FSSAI许可证,Urmi努力向更多人提供其产品,还扩大其销售范围。

在2017年Laabh Panchami吉日,阿图为其新发电厂揭幕—这是公司历史上最大的项目。 由DCS控制发电厂的锅炉、煤电厂、涡轮机、除灰装置,大约80人的团队负责整个工厂。 高度106m,作为本项目一部分建造的RCC烟囱是阿图最高的建筑物。

On October 25, 2017 on the auspicious occasion of Laabh Pancham (Gyaan Panchami), our Colors Business inaugurated its new Analytical laboratory at Atul. Well-equipped with the latest spectroscopic instruments, this state-of-the-art facility will enhance the quality assurance of dyes and…

在2017年10月25日的Laabh Pancham(Gyaan Panchami)吉日,Colors Business为阿图新的分析实验室举行了落成仪式。 配备最新的光谱仪,这一现代化设备将提高阿图供应染料和高性能颜料的质量保证。

Atul will be participating at AgroChemEx Shanghai, 2017. AgroChemEx is an annual agrochemical symposium and exhibition organised by the China Crop Protection Industry Association. It provides a valuable platform for the exchange of information and business development opportunities by attracting…

Efficax, launched by Atul, is a super spreader surfactant for agriculture use with high penetration. Key features of this product are outlined below. 100% pure trisiloxane increases efficacy of crop care chemicals used improves spraying efficiency safe to use with…

2017年9月30日和10月1日举行了第21届印度学校证书学校协会(ASISC)—全国水上运动会。Atul Vidyalaya在Atul Ltd.的赞助下,第四次主办这项活动,为期两天的活动因国内外不同ASISC学校的游泳爱好者而取得了成功。比赛包括自由泳、蛙泳、仰泳和蝶泳。马哈拉施特拉邦获得系列赛冠军。

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (m Pas) : 700 – 1,200 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (m Pas) : 700 – 1,200 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90

Sadhguru及其团队正在从科摩林角走陆路前往喜马拉雅山区,这是河流集会的一部分,该活动旨在提高人们对河流枯竭的认识和迫切需要拯救河流。阿图位于Par河畔,是这次行程的中途停留地。阿图 Vidyalaya的学生们高喊nadi stuti,热烈欢迎Sadhguru。他还在校园里种了一棵椰枣树。

Mixing ratio (Parts by weight) : 100 : 38 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 110 – 160 | Glass transition temperature (Tg) (o) : 115 – 130

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 8.15 – 9.50 | Viscosity @ 25oC (mPa s) : 100 – 200

Epoxy value (Eq/kg) : 2.15 – 2.22 | Viscosity @ 25oC (mPa s) : 160 – 190 | Softening point (oC) : 65 – 75 |

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio (Parts by weight) : 100 : 70 | Glass transition temperature (Tg) (oC) : 100 – 110 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 80 : 0 – 8 | Glass transition temperature (Tg) (oC) : 105 – 115 | Thermal class :…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 75 – 85

Appearance : Yellow to brown liquid | Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 100 – 300 | Amine value (mg KOH/g) : 628 – 634 | Mixing ratio (Parts by weight) : 24

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 5 – 15 | Pot life @ 25oC (hours) : 7 – 9 | Mixing ratio (Parts by weight) : 32

2017 marks the 70th anniversary of Atul Ltd. The history of the Company is closely linked to that of independent India: both started their journey in 1947 and endeavour to consistently improve over the years. In light of this, Polymers…

Polymers Retail is launching a new range of maintenance products under the brand Lacare for automobile, industrial and household applications. The upcoming product portfolio for this maintenance range is as follows: Generic name Application Multi-purpose maintenance spray Penetrates rust and…

Polymers Retail had a pilot launch of its retail module from April-June 2017 in Valsad, Pardi and Udwada. While it has been challenging for the Business to move from a no presence zone to a significant presence zone, the experience…

Polymers Performance Materials participated in ICERP 2017 in Mumbai. The exhibition was held on 10 – 12 January 2017. It gave us an opportunity to personally meet and discuss with the various personnel and decision makers of composites industry.

Atul Ltd received a certificate of merit for its greening the desert project by Flame Awards Asia, 2016

These fresh Barhee dates are from Atul’s farms in the beautiful Thar desert in Rajasthan and farmer fields in various parts of India, cultivated with Atul’s tissue culture raised date palms.

Colors Business launched an innovative mobile application for effective customer service and was conferred with the Customer Excellence award.

Dr GVG Rao, President, Colors Business, inaugurated new machinery at the Technical Services (TS) laboratory, Atul. The TS laboratory focuses on customer support activities, particularly textile dyeing and printing application techniques.

A representative from Colors Business participated in and conducted a technical seminar on ‘Selection, Evaluation, Application and Disposal of Dyes and Chemicals’ in Ethiopia. The seminar was organised by the Ethiopian Textile Industry Development Institute in twinning partnership with the…

阿克苏诺贝尔和阿图宣布其打算在印度共同投资生产一氯乙酸(MCA)。这将包括在Atul位于瓦尔萨德(古吉拉特邦)的第一个生产基地建立世界级的MCA工厂。每位合伙人将持有50%的股份。 该合作关系的建立依据包括,阿图在2,4-D(除草剂,使用MCA作为主要原料)全球领先供应方面具有领导地位,阿克苏诺贝尔在MCA市场具有全球领导地位,在荷兰、中国、日本和美国设有工厂。MCA是化学工业必不可少的组成部分,可用于各种化学品。 该合作伙伴关系将使用阿图生产的氯和氢来生产氯乙酸,利用阿图现有的基础设施和阿克苏诺贝尔提供的领先的环保氢化技术进行生产。该工厂将生产足够的MCA,满足阿图的垄断要求;阿克苏诺贝尔主要在印度销售其余产品。

在Ambedkar Jayanti节日之际,Niti Aayog的Digi Dhan Vyapar Yojana下的莫蒂总理宣布瓦尔萨德的Atul Ltd镇为印度七十五个“无现金城镇”之一,超过75%的交易通过数字模式支付而非现金。选定启动的城镇已接受独立第三方Price Waterhouse Coopers(PWC)的评估,只有审查期间超过80%的城镇交易总额通过数字模式支付的城镇才纳入该列表。

A bio-stimulant derived from seaweed extract (Ascophyllum nodusum). The product is used as a plant growth stimulant, enhancing plant vigour at critical stages and improving crop productivity.

A silicone based surfactant used as a tank mix with and herbicides, insecticides and fungicides to improve its bio-efficacy.

A selective pre-emergence herbicide used to control most grasses and some broad-leaved weeds in various crops.

A selective pre-emergence herbicide used to control most grasses and some broad-leaved weeds in various crops.

A selective pre and early post-emergence herbicide of the Triazine group used to control a wide range of grasses and broad-leaved weeds in maize and sugarcane.

A broad spectrum systemic post-emergence herbicide used to control grassy weeds such as Echinochloa spp, sedges and broad-leaved weeds in paddy.

A selective, pre-emergence herbicide used to control most grasses and some broad-leaved weeds in transplanted paddy.

A non-selective, post-emergence contact herbicide used to control annual grasses and broad-leaved weeds in tea, row crops and non-crop areas.

A systemic insecticide with protective and curative action used to control blast in paddy.

A sulphur based fertiliser for soil application used to overcome sulphur deficiencies and nutrition stress in plants and the soil.

An inorganic contact fungicide with protective action and acaricidal activity. The product is recommended for controlling powdery mildews in various crops.

A broad spectrum systemic fungicide of the Benzimidazole group used to control a range of diseases in various crops, with its protective and curative action.

A broad spectrum contact and protective fungicide and bactericide used to control wide range of fungal diseases in various crops.

A systemic insecticide of the Neonicotinoid and Phenylpyrazole group with contact and stomach action. The product is used to control chewing and sucking insect pests.

A broad spectrum insecticide and acaricide of the Organophosphorus group used to control a range of chewing and sucking insects in various crops.

A broad spectrum insecticide | miticide of the Synthetic pyrethroids group with contact and stomach action. The product is effective against a broad range of lepidopteran pests, sucking pests, mites and termites in various crops.

A non-systemic insecticide of Organophosphorus and Synthetic pyrethroids group with contact and stomach action. The product is used to control chewing and sucking insect pests.

One-component, solvent free, nearly instant setting adhesive. The product is ideal for applications such as bonding of marble, glass, metal, plastic, wood, sun board and flex and filling gaps in PVC doors. Lapox Ultraquick is available in the pack size…

A systemic fungicide that is used to control scab in apple, tikka leaf spot in groundnut, powdery mildew in mango and blast and sheath blight in rice.

A systemic fungicide of the Triazole group used to control fungal diseases. The product finds an application in wood preservation.

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 25 – 35

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : Thixotropic | Pot life @ 25oC (minutes) : 3 – 7

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 200 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) oC : 105 –…

Mixing ratio (Parts by weight) : 100 : 40 | Mix viscosity @ 25oC (mPa s) : Thixotropic | Pot life @ 25oC (minutes) : 35 – 45

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 100 – 110

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 6,000 – 8,000 | Pot life @ 25oC (minutes) : 15 – 300

Mixing ratio (Parts by weight) : 100 : 65 | Mix viscosity @ 25oC (mPa s) : 8,000 – 10,000 | Pot life @ 25oC (minutes) : 15 – 330

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 43 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 30 – 35

Mixing ratio (Parts by weight) : 100 : 55 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 45 – 60

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : 35 – 330

Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 25 – 35

Mix viscosity @ 25oC (mPa s) : 600 – 1,000 | Pot life @ 25oC (minutes) : 130 – 150

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,500 – 4,500 | Pot life @ 25oC (minutes) : 110 – 130

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,500 | Pot life @ 25oC (minutes) : 60 – 80

Mixing ratio (Parts by weight) : 100 : 66 | Mix viscosity @ 25oC (mPa s) : 4,500 – 5,500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 50,000 – 1,00,000 | Pot life @ 25oC (minutes) : 35 – 50

Mixing ratio (Parts by weight) : 100 : 80 | Mix viscosity @ 25oC (mPa s) : 75,000 – 1,25,000 | Pot life @ 25oC (minutes) : 8 – 10

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 2,500 – 3,000 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 190 – 220

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 120 – 180 | Glass transition temperature (Tg) (oC) : 130 – 140

Mixing ratio (Parts by weight) : 100 : 20 | Mix viscosity @ 25oC (mPa s) : Paste (colourless) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 95 – 115

Mixing ratio (Parts by weight) : 100 : 10 | Mix viscosity @ 25oC (mPa s) : Paste (blue) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 6 | Mix viscosity @ 25oC (mPa s) : Paste (grey) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 85 – 95

Mixing ratio (Parts by weight) : 100 : 14 | Mix viscosity @ 25oC (mPa s) : Paste (white) | Pot life @ 25oC (minutes) : 25 – 30 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 38 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 110 – 160 | Glass transition temperature (Tg) (oC) : 115 – 130

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 111,000 – 13,000

A cost effective substitute for cresylic acid and phenol.

An economical trichromatic navy dye with good dischargeability. The product is used to develop medium to dark shades.

A deep red dye used for scarlet, dark red, brown and burgundy shades.

A red dye with high tinctorial strength and excellent build-up properties. The product is used to develop medium to dark shades.

A golden yellow dye with high tinctorial strength used to develop deep shades with good all round fastness properties.

A basic trichromatic golden yellow dye with good dischargeability.

A blue dye with good light fastness properties used for pale to medium shades.

A red dye with good light fastness properties used for pale to medium shades.

A yellow dye with good light fastness properties used for pale to medium shades.

An economical navy dye with good build-up properties.

A black dye used to develop black to grey shades. The product has good light fastness properties.

A turquoise dye with good build-up properties.

A turquoise dye with good build-up properties.

A brilliant reddish blue dye used to develop bright royal blue shades.

A trichromatic blue dye with good fastness properties. The product has good dischargeability.

A bright violet dye used for various shades of violet.

An economical bluish red dye used for medium and dark shades.

An economical trichromatic red dye with high tinctorial strength.

A bright orange dye used for orange and scarlet shades.

An economical golden yellow dye used in trichromatic combinations.

A bright yellow dye used in tertiary combinations with good light fastness properties.

A yellow dye with all round fastness properties.

An ideal grey component with excellent performance in Exhaust and Continuous dyeing applications by Soft flow and Pad Dry Pad steam techniques. The product has good all round fastness properties. It is available in Microperle and Micro disperse varieties.

A navy dye with excellent build-up properties used for coloration of workwear and institutional wear. The product is used in combination with Yellow 3R and Jade Green XBN for Exhaust application. It shows minimum shade change when used with flame…

A systemic fungicide with protective and curative action used to control broad spectrum fungal diseases in various field crops and fruits.

A selective and systemic post-emergence herbicide readily absorbed by leaves. The product is used to control annual and perennial broad-leaved weeds in a range of crops.

A high purity grade of para Cresol for niche applications.

A starting ingredient in most versatile phenolic group antioxidants.

A naturally sourced aroma ingredient with a musk-like profile.

A key ingredient in specialty fragrance formulations.

An intermediate widely used by the Pharmaceuticals and Crop Protection Chemicals industry.

An aroma ingredient with sweet, floral, fennel and basil-like, mildly fruity odour. The product finds a major application in oral care products, flavours and fragrances.

A key building block for Dextromethorphan, a widely used formulation to treat cough and cold.

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 600 – 1,000 | Pot life @ 25oC (minutes) : 130 – 150

Mixing ratio (Parts by weight) : 100 : 66 | Mix viscosity @ 25oC (mPa s) : 4,500 – 5,500 | Pot life @ 25oC (minutes) : 40 – 50

Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 7,000 – 11,000 | Amine value (mg KOH/g) : 400 – 450 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight)…

Type of system : Pre-filled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 26 | Glass transition temperature (Tg) (oC) : 70 – 80 | Thermal class : F

Type of system : Pre-filled | Nature : Cold cure / Indoor | Mixing ratio (Parts by weight) : 100 : 25 | Glass transition temperature (Tg) (oC) : 60 – 70 | Thermal class : B

Type of system : Unfilled | Nature : Hot cure Indoor | Voltage class : MV / HV | Mixing ratio (parts by weight) : 100 : 15 | Glass transition temperature (Tg) (oC) : 80 – 90 | Thermal…

Appearance : Yellow liquid | Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 1,000 – 2,500 | Amine value (Eq/kg) : 8.00 – 9.00 | Mixing ratio (Parts by weight) : 34

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (Parts by weight) : 100 : 100 : 0.0 – 0.2 | Glass transition temperature (Tg) (oC) : 90 – 100 | Thermal class :…

Colour (Gardner) : Max 10 | Epoxy value (Eq/kg) : 2.20 – 2.60 | Viscosity @ 25oC (mPa s) : 20 – 50 | HyCl (%) : Max 1.00

Colour (Gardner) : Max 13 | Epoxy value (Eq/kg) : 1.80 – 2.40 | Viscosity @ 25oC (mPa s) : 40 – 70 | HyCl (%) : Max 1.00

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.10 – 4.50 | Viscosity @ 25oC (mPa s) : 20 – 35 | HyCl (%) : Max 0.20

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.90 – 6.30 | Viscosity @ 25oC (mPa s) : 6 – 8 | HyCl (%) : Max 0.20

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.30 – 6.00 | Viscosity @ 25oC (mPa s) : 6 – 8 | HyCl (%) : Max 0.20

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (Parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoo | Mixing ratio (parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 25 | Glass transition temperature (Tg) (oC) : 122 – 132 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC) : 90 – 105 | Thermal class : H

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC): 105 – 125 | Thermal class : H

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 100 : 0.5 – 1.5 : 0 – 20 | Glass transition temperature (Tg) (oC): 85 – 95 | Thermal class :…

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC) : 75 – 85 | Thermal class : F

Colour (Gardner) : Max 6 | Epoxy value (Eq/kg) : 1.54 – 2.00 | Viscosity @ 25oC (mPa s) : 250 – 500

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 80 : 0.5 – 2.0 | Glass transition temperature (Tg) (oC) : 75 – 85 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio (Parts by weight) : 100 : 90 | Glass transition temperature (Tg) (oC): 100 – 110 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 90 : 0.5 – 2.0 | Mix viscosity : 1,000/80 | Glass transition temperature (Tg) (oC): 100 – 110 | Thermal class…

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 7.00 – 8.00 | Viscosity @ 25oC (mPa s) : 100 – 200 | HyCl (%) : Max 0.15

Type of system : Pre-filled | Nature : Hot cure Indoor | Mixing ratio (parts by weight) : 100 : 100 | Glass transition temperature (Tg) (oC) : 110 – 120 | Thermal class : H

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.90 – 8.00 | Viscosity @ 25oC (mPa s) : 12 – 18 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 2.90 – 3.20 | Viscosity @ 25oC (mPa s) : 40 – 90 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.20 – 6.80 | Viscosity @ 25oC (mPa s) : 15 – 30 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 7.00 – 7.80 | Viscosity @ 25oC (mPa s) : 10 – 22 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.20 – 7.30 | Viscosity @ 25oC (mPa s) : Max 2 | HyCl (%) : Max 0.10

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 3.35 – 3.70 | Viscosity @ 25oC (mPa s) : 4 – 12 | HyCl (%) : Max 0.10

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.50 – 6.30 | Viscosity @ 25oC (mPa s) : 500 – 1,100

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.10 – 5.40 | Viscosity @ 25oC (mPa s) : 860 – 960

Mixing ratio (Parts by weight) : 100 : 40 | Mix viscosity @ 25oC (mPa s) : 50,000 – 1,00,000 | Pot life @ 25oC (minutes) : 20 – 25

Mixing ratio (Parts by weight) : 100 : 65 | Mix viscosity @ 25oC (mPa s) : 8,000 – 10,000 | Pot life @ 25oC (minutes) : 15 – 330

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.40 – 5.90 | Viscosity @ 25oC (mPa s) : 1,000 – 1,500

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.40 – 5.90 | Viscosity @ 25oC (mPa s) : 1,700 – 2,500

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 100 – 110

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 6,000 – 8,000 | Pot life @ 25oC (minutes) : 15 – 300

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 25 – 35

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) :100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 43 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 30 – 35

Mixing ratio (Parts by weight) : 100 : 55 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 45 – 60

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : 35 – 330

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,500 – 4,500 | Pot life @ 25oC (minutes) : 110 – 130

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,500 | Pot life @ 25oC (minutes) : 60 – 80

Chemistry : 3,3′-Diaminodiphenyl sulfone | Appearance : White to brownish white powder | Melting point (oC) : 167 – 175

Chemistry : 4,4′-Diaminodiphenyl sulfone Micronised | Appearance : White to off-white powder | Melting point (oC) : 176 – 180

Chemistry : 4,4′-Diaminodiphenyl sulfone Free Flow | Appearance : White to off-white powder | Melting point (oC) : 176 – 185

Chemistry : 4,4′-Diaminodiphenyl sulfone | Appearance : White to off-white powder | Melting point (oC) : 176 – 185

Chemistry : 4,4′-Diaminodiphenyl methane | Appearance : Viscous brownish liquid | Viscosity @ 60oC (mPa s) : 1,400 – 2,000

Appearance : Light yellow to brown liquid | Viscosity @ 25oC (mPa s) : 100 – 300

Chemistry : 4,4′-Diaminodicyclohexyl methane | Appearance : Colourless transparent liquid | Melting point (oC) : 35 – 37

Chemistry : 3,3’-Dimethyl-4,4’-diaminodicyclohexyl methane | Viscosity @ 25oC (mPa s) : 100 – 140

Colour (Gardner) : Yellow powder | Melting point (oC) : 155 – 158

Colour (Gardner) : Yellow solid | Viscosity @ 125oC (mPa s) : 50 – 500

Colour (Gardner) : Yellowish liquid | Solid content (%) : 74 – 76 | Viscosity @ 25oC (mPa s) : 100 – 400

Colour (Gardner) : Yellow solid | Viscosity @ 100oC (mPa s) : 1,000 – 7,000 | Softening point (oC) : 60 – 80

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 4.17 – 4.44 | Viscosity @ 85oC (mPa s) : 1,000 – 1,500

Epoxy value (Eq/kg) : 9.80 – 10.6 | Viscosity @ 25oC (mPa s) : 1,500 – 4,800

Epoxy value (Eq/kg) : 9.10 – 9.80 | Viscosity @ 25oC (mPa s) : 7,000 – 13,000

Epoxy value (Eq/kg) : 9.40 – 10.50 | Viscosity @ 25oC (mPa s) : 550 – 850

Epoxy value (Eq/kg) : 8.70 – 9.50 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000

Colour (Gardner) : Max 13 | Epoxy value (Eq/kg) : 5.88 – 6.66 | Viscosity @ 150oC (mPa s) : 30 – 55

Colour (Gardner) : Max 7 | Epoxy value (Eq/kg) : 7.52 – 8.47 | Viscosity @ 25oC (mPa s) : 7,000 – 12,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 8.55 – 9.00 | Viscosity @ 50oC (mPa s) : 3,000 – 6,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 7,000-19,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 17,000-19,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 13,000-15,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 10,000 – 12,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 7,000 – 11,000

Colour (Gardner) : Max 4 | Epoxy value (Eq/kg) : 5.12 – 6.10 | Viscosity @ 50oC (mPa s) : 100 – 350

Colour (Gardner) : Max 3 | Epoxy value (Eq/kg) : 5.59 – 5.81 | Viscosity @ 52oC (mPa s) : 1,100 – 1,700

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 6.50 – 7.50 | Viscosity @ 50oC (mPa s) : 1,000 – 2,500 | Hycl : Max 0.20

Colour (APHA) : Max 50 | Epoxy value (Eq/kg) : 5.71 – 5.95 | Viscosity @ 25oC (mPa s) : 4,000 – 5,000

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.26 – 5.55 | Viscosity @ 25oC (mPa s) : 9,000 – 12,000

Epoxy value (Eq/kg) : 0.53 – 0.59 | Viscosity @ 25oC (mPa s) : 1,800 – 2,600 | Softening point (oC) : 110 – 120

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 15,000 – 35,000 | Amine value (mg KOH/g) : 290 – 325 | Pot life @ 25oC (minutes) : 40 – 85 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Amine value (mg KOH/g) : 490 – 550 | Pot life @ 25oC (minutes) : 30 – 55 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000 | Amine value (mg KOH/g) : 300 – 350 | Pot life @ 25oC (minutes) : 50 – 65 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 3 | Viscosity @ 25oC (mPa s) : 40 – 60 | Amine value (mg KOH/g) : 320 – 340 | Pot life @ 25oC (minutes) : 25 – 40 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 10 – 20 | Pot life @ 25oC (minutes) : 90 – 120 | Mixing ratio (Parts by weight) : 23

Colour : Max 2 | Viscosity @ 25oC (mPa s) : 1,500 – 2,000 | Amine value (Eq/kg) : 165 – 210 | Pot life @ 25oC (hours) : 4 – 6 | Mixing ratio (Parts by weight) : 30…

Colour (Gardner) : Clear liquid | Viscosity @ 25oC (mPa s) : 850 – 1,200 | Mixing ratio (Parts by weight) : 100 (with resin ARL-148)

Colour (Gardner) : Black | Viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : Min 20 | Mixing ratio (Parts by weight) : 100 (with resin ARB – 28)

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 2,900 – 3,600 | Amine value (mg KOH/g) : 398 – 415 | Pot life @ 25oC (minutes) : 15 – 30 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 200 – 300 | Amine value (Eq/kg) : 17.00 – 17.80 | Pot life @ 25oC (minutes) : 25 – 35 | Mixing ratio (Parts by weight) :…

Colour (Gardner) : Max 5 | Viscosity @ 25oC (mPa s) : Max 10 | Pot life @ 25oC (minutes) : 20 – 25 | Mixing ratio (Parts by weight) : 10 – 12

Colour (Gardner) : Max 3 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight) : 10 – 12

Colour (Gardner) : Max 5 | Viscosity @ 25oC (mPa s) : 100 – 550 | Amine value (mg KOH/g) : 500 – 1,000 | Pot life @ 25oC (minutes) : 5 – 30 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 500 – 1,000 | Amine value (mg KOH/g) : 650 – 750 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 5 – 10 | Amine value (mg KOH/g) : 680 – 720 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 30 – 100 | Amine value (mg KOH/g) : 290 – 320 | Pot life @ 25oC (minutes) : 100 – 125 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 50 – 60 | Pot life @ 25oC (minutes) : 35 – 50 | Mixing ratio (Parts by weight) : 15

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 5,000 – 7,500 | Amine value (Eq/kg) : 4.40 – 5.10 | Mixing ratio (Parts by weight) : 60

Mixing ratio (Parts by weight) : 100 : 15 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : 85 – 95 | Glass transition temperature (Tg) (oC) : 95 – 105

Mixing ratio (Parts by weight) : 100 : 15 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : 20 – 25 | Glass transition temperature (Tg) (oC) : 95 – 105

Colour (APHA) : Max 100 | Epoxy value (Eq/kg) : 4.16 – 4.54 | Viscosity @ 25oC (mPa s) : 2,000 – 4,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 6.00 – 6.40 | Viscosity @ 25oC (mPa s) : 1,200 – 1,600

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.30 | Viscosity @ 25oC (mPa s) : 5,000 – 7,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.10 | Viscosity @ 25oC (mPa s) : 3,300 – 4,100

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.10 | Viscosity @ 25oC (mPa s) : 2,000 – 3,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.70 – 6.30 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000

Epoxy value (Eq/kg) : 1.07 – 1.16 | Viscosity @ 25oC (mPa s) : 620 – 900 | Softening point (oC) : 100 – 110

Epoxy value (Eq/kg) : 1.25 – 1.40 | Viscosity @ 25oC (mPa s) : 500 – 700 | Softening point (oC) : 95 – 101

Mixing ratio (Parts by weight) : 100 : 3-6 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 165 – 180

Mixing ratio (Parts by weight) : 100 : 32-40 : 1-3 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 170 – 185

Mixing ratio (Parts by weight) : 100 : 64 : 1-3 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 34 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) oC : 145 – 155

Mixing ratio (Parts by weight) : 100 : 100 : 1-3 | Mix viscosity @ 25oC (mPa s) : 400 – 700 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 95 –…

Mixing ratio (Parts by weight) : 100 : 27 | Mix viscosity @ 50oC (mPa s) : 3,000 – 5,000 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 150 – 160

Mixing ratio (Parts by weight) : 100 : 95 : 0.5-2.0 | Mix viscosity @ 25oC (mPa s) : 1,900 – 2,100 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 165 –…

Mixing ratio (Parts by weight) : 100 : 90 | Mix viscosity @ 25oC (mPa s) : 300 – 600 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 115 – 125

Mixing ratio (Parts by weight) : 100 : 90 : 1-3 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 115 –…

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 200 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 105 –…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 400 – 700 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 1,200 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 1,200 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 800 | Pot life @ 25oC (minutes) : 7 – 9 hr | Glass transition temperature (Tg) oC : 85 –…

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 1,200 – 1,500 | Pot life @ 25oC (minutes) : 120 – 150 | Glass transition temperature (Tg) oC : 55 – 65

Mixing ratio (Parts by weight) : 100:32 | Mix viscosity @ 25oC (mPa s) : 600 – 800 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 20 | Mix viscosity @ 25oC (mPa s) : Paste (colourless) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 95 – 115

Mixing ratio (Parts by weight) : 100 : 10 | Mix viscosity @ 25oC (mPa s) : Paste (blue) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 14 | Mix viscosity @ 25oC (mPa s) : Paste (white) | Pot life @ 25oC (minutes) : 25 – 30 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 24 | Mix viscosity @ 25oC (mPa s) : 250 – 400 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 125 – 135

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 3.57 – 4.45 | Viscosity @ 25oC (mPa s) : 450 – 800

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 800 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 75 – 85

Epoxy value (Eq/kg) : 1.08 – 1.18 | Viscosity @ 25oC (mPa s) : 430 – 550 | Softening point (oC) : 90 – 100

Epoxy value (Eq/kg) : 1.23 – 1.33 | Viscosity @ 25oC (mPa s) : 480 – 580 | Softening point (oC) : 80 – 90

Epoxy value (Eq/kg) : 1.33 – 1.40 | Viscosity @ 25oC (mPa s) : 500 – 600 | Softening point (oC) : 95 – 101

Mixing ratio (Parts by weight) : 100 : 5 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 15 : 2 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 155 – 165

Mixing ratio (Parts by weight) : 100 : 32 : 1-3 | Pot life @ 25oC (weeks) : 2 – 3 | Glass transition temperature (Tg) (oC) : 130 – 140

Mixing ratio (Parts by weight) : 100 : 23 : 0.5-3.0 | Pot life @ 25oC (weeks) : 2 – 3 | Glass transition temperature (Tg) (oC) : 130 – 140

Epoxy value (Eq/kg) : 1.25 – 1.35 | Viscosity @ 150oC (mPa s) : 4,500 – 6,500 | Glass transition temperature (Tg) (oC) : 55

Mixing ratio (Parts by weight) : 100 : 35 : 1-3 | Pot life @ 25oC (weeks) : 6 – 8 weeks | Glass transition temperature (Tg) (oC) : 150 – 160

Epoxy value (Eq/kg) : 1.42 – 1.53 | Viscosity @ 25oC (mPa s) : 375 – 475 | Softening point (oC) : 80 – 90

Appearance : Clear yellow liquid | Colour (Gardner) : Max 6 | Viscosity @ 25oC (mPa s) : 150 – 300 | Amine value (mg KOH/g) : 580 – 635

Mixing ratio (Parts by weight) : 100 : 27 | Pot life @ 25oC (hours) : > 4 | Glass transition temperature (Tg) (oC) : 150 – 160

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 300 – 600 | Amine value (mg KOH/g) : 260 – 310 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 150 – 300 | Amine value (mg KOH/g) : 335 – 375 | Pot life @ 25oC (minutes) : 25 – 40 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 50 – 150 | Amine value (mg KOH/g) : 340 – 390 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 600 – 900 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 130 –…

Colour (Gardner) : Max 2 | Amine value (mg KOH/g) : 330 – 360 | Pot life @ 25oC (minutes) : 20 – 50 | Mixing ratio (Parts by weight) : 45

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 1,500 – 2,500 | Pot life @ 25oC (minutes) : 300 – 350 | Glass transition temperature (Tg) (oC) : 130 – 140

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 400 – 600 | Amine value (mg KOH/g) : 250 – 300 | Pot life @ 25oC (minutes) : 30 – 45 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 12 | Viscosity @ 25oC (mPa s) : 1,000 – 2,000 | Amine value (mg KOH/g) : 280 – 300 | Pot life @ 25oC (minutes) : 46 – 65 | Mixing ratio (Parts by weight)…

Colour (Gardner) : Max 10 | Viscosity @ 25oC (mPa s) : 2,500 – 5,500 | Amine value (mg KOH/g) : 202 – 225 | Pot life @ 25oC (minutes) : 80 – 100 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 500 – 1,000 | Amine value (mg KOH/g) : 425 – 450 | Pot life @ 25oC (minutes) : 120 – 130 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 9 | Viscosity @ 25oC (mPa s) : 12,000 – 18,000 | Amine value (mg KOH/g) : 350 – 400 | Pot life @ 25oC (minutes) : 60 – 80 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 9 | Viscosity @ 25oC (mPa s) : 45,000 – 60,000 | Amine value (mg KOH/g) : 290 – 320 | Pot life @ 25oC (minutes) : 110 – 130 | Mixing ratio (Parts by weight)…

Mixing ratio (Parts by weight) : 100 : 6 | Mix viscosity @ 25oC (mPa s) : Paste (grey) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 85 – 95

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 2,500 – 3,000 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 190 – 220

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 100 – 110

Colour (Gardner) : Max 9 | Viscosity @ 40oC (mPa s) : 50,000 – 75,000 | Amine value (mg KOH/g) : 210 – 230 | Mixing ratio (Parts by weight) : 100 – 125

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 700 – 900 | Amine value (Eq/kg) : 4.70 – 5.00 | Mixing ratio (Parts by weight) : 60

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 120 – 180 | Glass transition temperature (Tg) (oC) : 130 – 140

Appearance : Dark brown liquid | Colour (Gardner) : Max 16 | Viscosity @ 25oC (mPa s) : 15,000 – 21,000 | Amine value (Eq/kg) : 4.40 – 4.80 | Mixing ratio (Parts by weight) : 60

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 3,800 – 5,800 | Amine value (Eq/kg) : 4.70 – 5.10 | Mixing ratio (Parts by weight) : 60

Epoxy value (Eq/kg) : Max 0.08 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000 | Non-volatile content (%) : 49 – 51 (160oC/2h)

Epoxy value (Eq/kg) : 1.80 – 2.20 | Viscosity @ 25oC (mPa s) : 14,000 – 20,000 | Non-volatile content (%) : 74 – 76 (150oC/2h)

Epoxy value (Eq/kg) : 1.90 – 2.20 | Viscosity @ 25oC (mPa s) : 9,000 – 13,000 | Non-volatile content (%) : 74 – 76 (150oC/2h)

Epoxy value (Eq/kg) : 3.10 – 3.40 | Viscosity @ 25oC (mPa s) : 600 – 850 | Non-volatile content (%) : 79 – 81 (150oC/1h)

Colour (Gardner) : Max 3 | Epoxy value (Eq/kg) : 5.50 – 6.00 | Viscosity @ 25oC (mPa s) : 25,000 – 35,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.40 – 4.60 | Viscosity @ 25oC (mPa s) : 800 – 1,500 | Non-volatile content (%) :79 – 81 (150oC/1h)

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.40 – 4.60 | Viscosity @ 25oC (mPa s) : 150 – 350 | Non-volatile content (%): 79 – 81 (105oC/2h)

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 22 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 140 – 155

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 170 – 200

Mixing ratio (Parts by weight) : 100 : 35 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 300 – 350 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 350 – 450 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 15 : 1-3 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 40 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 180 – 200

Appearance : Clear brown liquid | Viscosity @ 25oC (mPa s) : 1,000 – 1,800

Appearance : White crystalline powder | Melting point (oC) : Min 75

Appearance : Brown liquid or solid | Viscosity @ 25oC (mPa s) : Max 100 | Melting point (oC) : 36 – 42

Appearance : Clear liquid | Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 10 – 30

Appearance : Clear liquid | Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : Max 10

Appearance : White crystal | Melting point (oC) : Min 127 – 134

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.50 – 5.70 | Viscosity @ 52oC (mPa s) : 20,000 – 50,000

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.20 – 6.20 | Viscosity @ 25oC (mPa s) : 20 – 50 | HyCl (%) : Max 0.20

Chemistry : 3,3′-Diethyl-4,4′-diaminodiphenyl methane| Appearance : Dark brown liquid | Viscosity @ 40oC (mPa s) : 250 – 400

Chemistry : 4,4′-Diaminodiphenyl methane | Appearance : White to tan pastilles | Melting point (oC) : 88 – 92

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.50 – 5.75 | Viscosity @ 25oC (mPa s) : 4,500 – 6,500

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.55 – 5.80 | Viscosity @ 25oC (mPa s) : 6,500 – 8,500

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.20 – 5.50 | Viscosity @ 25oC (mPa s) : 450 – 650

Colour (Gardner) : Max 1 | Colour (AHPA) : Max 75 | Epoxy value (Eq/kg) : 5.12 – 5.55 | Viscosity @ 25oC (mPa s) : 500 – 700

Colour (Gardner) : Max 1 | Colour (APHA) : Max 150 | Epoxy value (Eq/kg) : 4.65 – 5.12 | Viscosity @ 25oC (mPa s) : 500 – 700

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.00 – 5.50 | Viscosity @ 25oC (mPa s) : 4,500 – 5,500

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 7.00 – 7.80 | Viscosity @ 25oC (mPa s) : 10 – 22 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.00 – 5.50 | Viscosity @ 25oC (mPa s) : 1,500 – 2,000

Colour (Gardner) : Milky white liquid | Epoxy value (Eq/kg) : 4.80 – 5.10 | Viscosity @ 25oC (mPa s) : 550 – 750

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.90 – 5.20 | Viscosity @ 25oC (mPa s) : 800 – 1,200

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.25 – 5.45 | Viscosity @ 25oC (mPa s) : 11,000 – 15,000

Colour (APHA) : Max 50 | Epoxy value (Eq/kg) : 5.25 – 5.45 | Viscosity @ 25oC (mPa s) : 8,000 – 11,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.30 – 4.70 | Viscosity @ 25oC (mPa s) : 20,000 – 28,000

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.25 – 5.45 | Viscosity @ 25oC (mPa s) : 11,000 – 15,000

Epoxy value (Eq/kg) : 0.34 – 0.42 | Viscosity @ 25oC (mPa s) : 5,000 – 10,000 | Softening point (oC) : 125 – 140

Chemistry : 3,3′-Diaminodiphenyl sulfone Micronised | Appearance : Off-white to yellowish brown powder | Melting point (oC) : 167 – 175

Epoxy value (Eq/kg) : 1.12 – 1.20 | Viscosity @ 25oC (mPa s) : 550 – 700 | Softening point (oC) : 90 – 102

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : Thixotropic paste | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : Thixotropic paste | Pot life @ 25oC (minutes) : 50 – 70 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : Thixotropic paste | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : Thixotropic paste | Pot life @ 25oC (minutes) : 130 – 170 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 40 | Mix viscosity @ 25oC (mPa s) : Thixotropic | Pot life @ 25oC (minutes) : 35 – 45

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 50,000 – 1,00,000 | Pot life @ 25oC (minutes) : 35 – 50

Mixing ratio (Parts by weight) : 100 : 80 | Mix viscosity @ 25oC (mPa s) : 75,000 – 1,25,000 | Pot life @ 25oC (minutes) : 8 – 10

Mixing ratio (Parts by weight) : 100 : 10 | Mix viscosity @ 25oC (mPa s) : 4,000 – 6,000 | Pot life @ 25oC (minutes) : 20 – 30

Type of system : Unfilled | Nature : Cold cure / Indoor | Mixing ratio (Parts by weight) : 100 : 10 | Glass transition temperature (Tg) (oC) : 60 – 70

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 25 – 35

Mixing ratio (Parts by weight) : 100 : 80 | Mix viscosity @ 25oC (mPa s) : 32,000 – 37,000 | Pot life @ 25oC (minutes) : 90 – 105

Mixing ratio (Parts by weight) : 100 : 80 | Mix viscosity @ 25oC (mPa s) : 75,000 – 1,25,000 | Pot life @ 25oC (minutes) : 8 – 10

Mixing ratio (Parts by weight) : 100 : 10 | Mix viscosity @ 25oC (mPa s) : 600 – 800 | Pot life @ 25oC (minutes) : 30 – 60

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 400 – 500 | Pot life @ 25oC (minutes) : > 60

Mixing ratio (Parts by weight) : 100 : 80 | Mix viscosity @ 25oC (mPa s) : 25,000 – 40,000 | Pot life @ 25oC (minutes) : 40 – 80

Mixing ratio (Parts by weight) : 100 : 27 | Pot life @ 25oC (minutes) : 170 – 190

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : Thixotropic | Pot life @ 25oC (minutes) : 3 – 7

Mixing ratio (Parts by weight) : 100 : 80 | Mix viscosity @ 25oC (mPa s) : 15,000 – 20,000 | Pot life @ 25oC (minutes) : 150 – 200

Mixing ratio (Parts by weight) : 100 : 15 | Pot life @ 25oC (minutes) : 85 – 95 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Glass transition temperature (Tg) (oC) : 95 – 105

Mixing ratio (Parts by weight) : 100 : 15 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : 20 – 25 | Glass transition temperature (Tg) (oC) : 95 – 105

Mixing ratio (Parts by weight) : 100 : 35 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 300 – 350 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 24 | Mix viscosity @ 25oC (mPa s) : 250 – 400 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 125 – 135

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (m Pas) : 600 – 750 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1,200 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (m Pas) : 600 – 800 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 75 – 85