“Una ojeada a la celebracíón del Día de la Mujer en Atul, Gujarat. Las mujeres talentosas, esforzadas y felices de nuestras oficinas contribuyen a hacer el equipo de Atul más potente.”

“Una ojeada a la celebracíón del Día de la Mujer en Atul, Gujarat. Las mujeres talentosas, esforzadas y felices de nuestras oficinas contribuyen a hacer el equipo de Atul más potente.”

El Floras Business de Atul Ltd participó hace poco en la edición de 2019 de SIAL Middle East, que tuvo lugar en el Centro Nacional de Exposiciones de Abu Dhabi.

Fue fantástico encontrarse con todo el mundo. El Mercado Global de Alimentos (en francés Salon International de l’Alimentation, o SIAL) es una feria de comercio que se celebra cada dos años y está centrada en la industria del procesamiento alimentario.

La Empresa cree que 5S es un factor clave para alcanzar su meta de un desarrollo sostenible. Iniciamos el movimiento 5S unos años atrás y hemos estado implementando la iniciativa en nuestras fábricas a un nivel básico. Es importante que avancemos al siguiente nivel de implementación de 5S. El relanzamiento del movimiento fue anunciado durante una reunión inaugural organizada el 28 de agosto de 2019 en el Salón Polivalente de Atul Vidyalaya.

El quipo se comprometió a llevar adelante el movimiento 5S para que sea un éxito. El nombre y el logo del movimiento – Swayam, fueron presentados. Los ganadores de los concursos de preguntas y de la elección del nombre fueron felicitados por nuestro Presidente y Director General. En su discurso, el Sr. Sunil Lalbhai pidió que el equipo asumiera la responsabilidad y fuese parte del cambio para fortalecer nuestras raíces a través de la mejora de los sistemas.

Appearance : Dark violet lumps | Colour (Gardner) : > 18 | Methylol content (%) : 12 – 16 | Softening point (oC): 85 – 105

Appearance : Pale yellow lumps | Colour (Gardner) : Max 6 | Methylol content (%) : 14 – 17 | Softening point (oC) : 90 – 100

Appearance : Pale yellow lumps | Colour (Gardner) : Max 4 | Methylol content (%) : 8 – 12 | Melting point, capillary (oC) : 63 – 75 | Softening point (oC) : 65 – 80

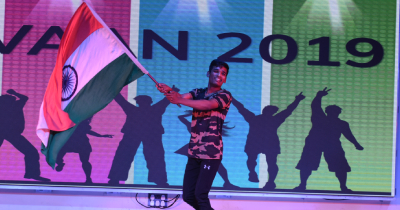

Se llevó a cabo en Atul la semana pasada Yuvaa, un programa de participación entretenido y lleno de diversión donde se mostraron los talentos de los miembros de nuestro equipo. El evento fomentó una mayor participación y la creación de lazos a través de una variedad de programas tales como canto, baile, teatro y shows de comedia.

La 42ª Asamblea General Anual de los Miembros de Atul Ltd se llevó a cabo el miércoles 31 de julio de 2019 en la Asociación de Gestion Ahmedabad en Ahmedabad.

El premio Green Gujarat Awards 2019 fue otorgado a Atul Ltd, Ankleshwar en el Día Mundial del Medio Ambiente, el 5 de junio de 2019. El premio fue recibido de manos del Sr. Ganpatbhai Vasava, el Honorable Ministro de Medio Ambiente y Bosques del Gobierno de Gujarat. El Honorable Ministro de Energía, Shri Suaravbhai Patel fue el Invitado Principal del evento. Se entregó un certificado de agradecimiento al equipo de Aromatics por su contribución al reciclaje y la reutilización de las aguas residuales. El evento fue impulsado por el Departamento de Cambio Climático del Gobierno de Gujarat y fue organizado por News 18.

El equipo de RE participó en la competición Kaizen, 5S para la Transformación Cultural en el Hogar, el Lugar de Trabajo y la Nueva India, celebrada el 21 y 22 de mayo de 2019 en Surat. Compartieron las mejores prácticas en la aplicación de las 5S en las respectivas unidades de Atul y también recibieron el Premio a la Excelencia 5S Kaizen.

An aroma ingredient to enhance pineapple, fruity, sweet and juicy odour, widely used by cosmetics and flavour industry.

An aroma chemical with fruity, wine and banana like odour, used to make flavours and fragrances for personal care industry.

A value added down-stream of ortho Cresol, which plays a key role in the manufacturing of hydrogen peroxide (H2O2). Atul Ltd is the only manufacturer of 2-Methylcyclohexyl acetate, with a captive source of ortho Cresol.

A dye intermediate in organic synthesis.

Atul organizó su Reunión anual de Analistas la semana pasada en Mumbai para compartir el desempeño de la Compañía.

Como un pequeño paso adelante en nuestro esfuerzo por impartir una educación de calidad a los niños de las aldeas del interior, la Fundación Atul donó recientemente cinco tabletas a una escuela de la aldea de Zilla Parishad en el taluka Maan de Satara, Maharashtra, afectado por la sequía.

Hasta ahora, esto ha permitido que 120 estudiantes vean videos educativos y amplíen su base de conocimientos.

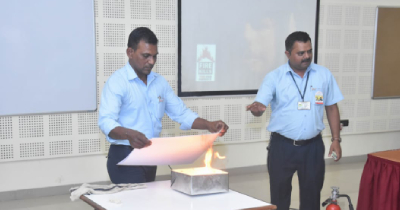

La 48th Semana Nacional de Seguridad se celebró del 4 al 11 de marzo de 2019. Se organizaron diversas actividades para crear conciencia sobre la seguridad industrial entre los miembros de la familia Atul.

Nuestro equipo de Protección de Cultivos participó en la Exposición Internacional de Agro químicos y Protección de Cultivos de China, en Shangai. Las empresas aprovecharon esta oportunidad para reunirse con clientes y socios comerciales para discutir productos, servicios y más.

Atul participó en la Cumbre Mundial Vibrant de Gujarat 2019. La Cumbre fue inaugurada por el Honorable Primer Ministro de la India, Shri Narendra Modi.

El Negocio de Materiales de Rendimiento de Polímeros participó en la ICERP 2019 que se celebró en el Centro de Exposiciones de Bombay en Mumbai. Las empresas aprovecharon esta oportunidad para compartir ideas y conocimientos técnicos con nuestros clientes.

Nouryan se ha asociado con la Fundación Atul para suministrar tabletas de hierro y ácido fólico a los estudiantes de tres institutos administrados por la Fundación. El objetivo de esta iniciativa es mejorar los niveles de hemoglobina de los estudiantes (en particular de los niños de las tribus). Tras realizar análisis de sangre, se identificó a los estudiantes con deficiencias de hierro y se les proporcionaron tabletas.

Como parte de esta iniciativa se llevaron a cabo varias sesiones de concienciación para estudiantes y padres sobre la importancia de una dieta equilibrada y de la actividad física.

Nos complace compartir que uno de los productos de Atul, Polygrip HVAC, se utilizó para el aislamiento de alta calidad de los conductos de CA durante la construcción de la Estatua de la Unidad que fue inaugurada hoy por Narendra Modi, el Primer Ministro de la India.

We are delighted to share that one of Atul’s products, Polygrip HVAC, was used for high-quality AC duct insulation during the construction of the Statue of Unity that was unveiled today by Narendra Modi, the Prime Minister of India.

Colour (Gardner) : Max 10 | Epoxy value (Eq/kg) : 7.00 – 8.00 | Viscosity @ 150oC (mPa s) : 2,500 – 4,000

Colour (Gardner) : Max 18 | Epoxy value (Eq/kg) : 7.40 – 8.50 | Viscosity @ 150oC (mPa s) : 2,000 – 4,000

Appearance : Clear colourless solution | Formaldehyde content: 37 ± 0.50 | Methanol content: Max 5 | Specific gravity

: 1.095 – 1.115 | pH : 2.80 – 5.00

Colour (APHA) : Max 50 | Epoxy value (Eq/kg) : 5.71 – 5.95 | Viscosity @ 25oC (mPa s) : 4,000 – 5,000

Atul Ltd ha ganado el 1er premio a la Excelencia en la Gestión de Costes en la 15ª edición de los Premios Nacionales presentados por el Instituto de Contadores de Costes de la India, en la categoría de Privado – Manufactura – Grande (con un volumen de negocios de entre 2.500 y 5.000 cr.). El premio fue presentado por Shri Piyush Goyal, el Honorable Ministro de la Unión de Ferrocarriles y Carbón.

Appearance : Clear colourless solution | Formaldehyde content: 37 ± 0.50 | Methanol content: Max 5 | Specific gravity

: 1.095 – 1.115 | pH : 2.80 – 5.00

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 6.50 – 7.50 | Viscosity @ 50oC (mPa s) : 1,000 – 2,500 | HyCl (%) : Max 0.20

Colour (Gardner) : Max 10 | Epoxy value (Eq/kg) : 7.00 – 8.00 | Viscosity @ 150oC (mPa s) : 2,500 – 4,000 | HyCl (%) : Max 0.10

Colour (Gardner) : Max 18 | Epoxy value (Eq/kg) : 7.40 – 8.50 | Viscosity @ 150oC (mPa s) : 2,000 – 4,000 | HyCl (%) : Max 0.10

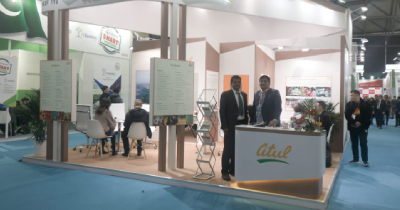

Las Empresas de Aromáticos, Químicos a Granel y Farmacéuticos participaron en Chemspec Europa que se celebró en Colonia (Alemania). Las empresas aprovecharon esta oportunidad para reunirse con clientes y socios comerciales para discutir productos, servicios y más.

Atul ha estado comprometida con la conservación del medio ambiente desde sus inicios. En el marco de las celebraciones del Día Mundial del Medio Ambiente, se organizaron diversas actividades para difundir la conciencia sobre el desarrollo sostenible, en particular la protección del medio ambiente. La semana de celebración comenzó con la proyección de un documental sobre “vencer la contaminación del plástico”. Los miembros del equipo y sus familias se reunieron para plantar arbolitos cerca de la Escuela Kalyani, la primera escuela creada por Atul. A esto le siguió una campaña de limpieza organizada en la colina de Parnera y la playa Tithal, Valsad.

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 10 – 50 | Pot life @ 25oC : 600 min – 700 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 10 – 50 | Pot life @ 25oC : 300 min – 380 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 20 – 100 | Pot life @ 25oC : 80 min – 100 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 20 – 100 | Pot life @ 25oC : 50 min – 60 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 50 – 150 | Pot life @ 25oC : 25 min – 35 hr | Mixing ratio (Parts by weight) : 32

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 150-300 | Pot life @ 25oC : 14 min – 20 hr

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 10 – 150 | Pot life @ 25oC : 10 min – 10 hr | Mixing ratio (Parts by weight) : 32

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 10 – 150 | Pot life @ 25oC : 10 min – 10 hr | Mixing ratio (Parts by weight) : 32

Atul Ltd organizó su reunión anual de analistas el 4 de mayo en Vivanta por el Presidente de Taj para compartir los detalles del rendimiento y los planes futuros de la empresa con los administradores de fondos, las empresas de gestión de activos, las empresas de corretaje, los fondos mutuos, los analistas y otras partes interesadas.

Alrededor de 200 personas asistieron al evento.

Para ver la presentación hecha en el Encuentro de Analistas, haga clic aquí.

Urmi fue fundada en 1953 por Atul Ltd. con el empoderamiento de las mujeres como objetivo. A lo largo de los años, las especias secadas al sol, machacadas y preparadas tradicionalmente se han convertido en la identidad de la organización. Cada paso del proceso de producción es atendido por mujeres de las aldeas circundantes.

Ahora compra en Urmi Dukan, la primera tienda al por menor creada por Urmi.

Para más información, por favor llave (+91) 81403 80444 o escriba a urmi@atul.co.in

Lacare® AM 70 is a multi-purpose maintenance spray especially designed to meet the requirements of preventive and corrective maintenance for industrial use, automobiles and common household applications.

Lacare® AM 70 is available in the pack size of 45 g, 85 g and 400 ml.

Lacare® Channel Spray is a superior polymer-based spray used for improving the sliding movement of glass used in car windows. It is especially made to lubricate the rubber beading, plastic and other assemblies used in the sliding windows of automobiles.

Lacare® Channel Spray is available in the pack size of 60 g.

Lacare® Chain Lube is a superior oil based chain lubricant for open chain of bike driven at very high speeds where the chain is exposed to moisture and dusty environments.

It is ideal for chains that are standard as well as with O-ring, X-ring and Z-ring.

Lacare® Chain Lube is available in the pack size of 70 g.

LAPOX® TILEGRIP: a high performance, cementitious tile fixing adhesive

APPLICATIONS

– Fixing floor and wall tiles (internal and external)

– Fixing thin bed tiles and medium format tiles

– Cladding of vitrified tiles, ceramic tiles, porcelain, mosaic, granite and marble

BENEFITS

– Non-skid, self-curing and highly durable

– Flexible and impact resistant

– Excellent adhesion and low shrinkage

– Does not require hacking or mechanical key to bond tiles

PACKAGING

20 kg

Lacare® is a recently introduced range of maintenance products for automobile, industrial and household applications.

Channel spray:

– Can be applied on rubber channels of glass windows used in cars

– Ensures the smooth movement of manual and power window glass

– Does not stain

– Guards rubber channels from hardening

– Easily penetrates into rubber channels

PACKAGING

60 g

Lacare® is a recently introduced range of maintenance products for automobile, industrial and household applications.

Chain Lube:

– Can be applied on open chains of bikes driven at high speeds + standard chains, O-ring chains, X-ring chains and Z-ring chains

– Increases chain life

– Resists water and rust

– Reduces friction

– Retains stickiness for a long duration

PACKAGING

70 g

Urmi fue fundada en 1953 por Atul Ltd. con un objetivo de empoderar a las mujeres comprometiéndolas en actividades con propósito. A lo largo de los años, las especias frescas y preparadas tradicionalmente, hechas a mano por mujeres de las aldeas circundantes, se han convertido en la identidad de la organización. Estas mujeres manejan todo el proceso de producción, desde el secado solar, el machacado hasta la mezcla y el empaquetado.

Estamos felices de darle la bienvenida a ser parte de nuestra jornada de crecimiento en Urmi. Para aquellos interesados en distribuir especias, por favor, pónganse en contacto con nosotros.

| Cantidad (de especias) | 20-40 kg | 41-60 kg | 61-80 kg |

| Comisión (% del valor total de la factura) | 10% | 12% | 15% |

(+91) 81403 80444

urmi@atul.co.in

Nos complace compartir que el Informe Anual 2016-17 de Atul ganó recientemente el Escudo de Plata por un jurado presidido por Shri M Damodaran, ex Presidente de la Junta de Valores y Bolsa de la India (SEBI), entre las entradas recibidas en la categoría de Sector Manufacturero de los Premios ICAI a la Excelencia en la Información Financiera para el año 2016-17.

Agradecemos al equipo involucrado por su contribución, apoyo y trabajo duro. Para ver nuestro Informe Anual, por favor haga clic aquí.

El equipo Atul te invita a visitar CAC 2018. Esperamos compartir más información sobre nuestros productos y experiencia técnica con nuestros clientes y socios.

Será un placer conocerle.

El negocio de Polymers Performance Materials se complace en invitarle a JEC WORLD | PAINTINDIA 2018.

Mostraremos toda nuestra gama de productos y lo consideraremos una oportunidad para compartir ideas y conocimientos técnicos con nuestros clientes.

¡Esperamos que pueda venir y deseamos verle!

No sólo el mundo de los negocios se benefició de la visión de Kasturbhai, sino que enriqueció el tejido educativo, social y cultural de nuestra nación con igual distinción. Fue su firme adhesión a los valores lo que lo hizo verdaderamente notable. Un astuto visionario y pionero, un humanitario dedicado y un líder de carácter excepcional, Kasturbhai llevó una vida que sigue inspirándonos cada día.

Estamos comprometidos con su visión e inclinamos nuestras cabezas en reverencia.

Lapox Metalam is a two-component modified epoxy system. The product is ideal for applications such as coating and laminating glass, metals, plastic, wood, paper stickers and natural stones. It is available in pack sizes of 1.5 kg and 7.5 kg.

Lapox Metalam is a two-component modified epoxy system. The product is ideal for applications such as coating and laminating glass, metals, plastic, wood, paper stickers and natural stones. It is available in pack sizes of 1.5 kg and 7.5 kg.

Lapox Granito is a two-component modified epoxy based system. The product is ideal for applications such as casting of decorative parts and table top. It is available in pack sizes of 1.25 kg, 5 kg and 10 kg.

Los representantes Atul de Aromáticos, Químicos a Granel y Negocios Farmacéuticos participaron en CPhI India, Mumbai, y se pusieron en contacto con clientes y socios para discutir las soluciones y los productos de alta calidad para satisfacer sus necesidades de fabricación únicas.

Fundada por Atul Ltd en 1953, Urmi trabaja para empoderar a las mujeres. Las especias frescas y tradicionalmente preparadas son la identidad de la organización. Las mujeres de las aldeas circundantes están dedicadas a secar, machacar, mezclar y envasar estas especias. El machacado da un aroma, apariencia y sabor distintos que diferencian los productos de los que se encuentran normalmente disponibles. El polvo de chile (suave, medio y picante), el polvo de comino de cilantro, el garam masala, el escabeche masala, el té masala y el polvo de cúrcuma son sus productos clave.

Con su licencia de FSSAI, Urmi se esfuerza por poner sus productos a disposición de más personas y ampliar su alcance.

En el auspicioso día de Laabh Panchami 2017, Atul inauguró su nueva planta de energía, el mayor proyecto de la historia de la Compañía.

Las calderas de la planta, la planta de carbón, la turbina y las unidades de manejo de cenizas de la planta son operadas por DCS, y toda la instalación es administrada por un equipo de unas 80 personas.

Con 106 m, la chimenea de RCC construida como parte de este proyecto es la estructura más alta de Atul.

On October 25, 2017 on the auspicious occasion of Laabh Pancham (Gyaan Panchami), our Colors Business inaugurated its new Analytical laboratory at Atul.

Well-equipped with the latest spectroscopic instruments, this state-of-the-art facility will enhance the quality assurance of dyes and high-performance pigments offered by Atul.

El 25 de octubre de 2017, en la auspiciosa ocasión de Laabh Pancham (Gyaan Panchami), nuestro Negocio de Colores inauguró su nuevo laboratorio Analítico en Atul.

Bien equipada con los últimos instrumentos espectroscópicos, esta instalación de última generación mejorará la garantía de calidad de los tintes y pigmentos de alto rendimiento que ofrece Atul.

Atul will be participating at AgroChemEx Shanghai, 2017.

AgroChemEx is an annual agrochemical symposium and exhibition organised by the China Crop Protection Industry Association.

It provides a valuable platform for the exchange of information and business development opportunities by attracting over 600 exhibitors, specialising in technical, formulation and adjuvants.

When

October 15-17, 2017

Where

Booth 2F45, Shanghai World Expo Exhibition and Convention Center, China

Efficax, launched by Atul, is a super spreader surfactant for agriculture use with high penetration. Key features of this product are outlined below.

Dosage: 25 ml per 100 lt of spray volume; 50 ml per acre

Sizes available: 50 ml, 100 ml, 250 ml, 500 ml

La 21ª Asociación de Escuelas para el Certificado Escolar Indio (ASISC) – Encuentro Acuático Nacional se celebró el 30 de septiembre y el 1 de octubre de 2017. El evento fue organizado por cuarta vez por Atul Vidyalaya bajo el patrocinio de Atul Ltd. Los entusiastas de la natación de diferentes escuelas ASISC del país y del extranjero hicieron que el evento de dos días fuera un éxito. Se organizaron carreras de estilo libre, pecho, espalda y mariposa. Maharashtra fue declarada como el ganador de la serie.

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (m Pas) : 700 – 1,200 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (m Pas) : 700 – 1,200 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90

Junto con su equipo, Sadhguru está viajando por carretera desde Kanyakumari al Himalaya como parte del Rally de Ríos, una iniciativa para difundir la conciencia sobre el agotamiento de los ríos y la urgente necesidad de salvarlos. Atul, situado a orillas del río Par, fue una parada en este viaje. Los estudiantes de Atul Vidyalaya dieron a Sadhguru una cálida bienvenida cantando el nadi stuti. También plantó una palmera de dátiles en el campus de la escuela.

Mixing ratio (Parts by weight) : 100 : 38 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 110 – 160 | Glass transition temperature (Tg) (o) : 115 – 130

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 8.15 – 9.50 | Viscosity @ 25oC (mPa s) : 100 – 200

Epoxy value (Eq/kg) : 2.15 – 2.22 | Viscosity @ 25oC (mPa s) : 160 – 190 | Softening point (oC) : 65 – 75 |

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio (Parts by weight) : 100 : 70 | Glass transition temperature (Tg) (oC) : 100 – 110 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 80 : 0 – 8 | Glass transition temperature (Tg) (oC) : 105 – 115 | Thermal class : F

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 75 – 85

Appearance : Yellow to brown liquid | Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 100 – 300 | Amine value (mg KOH/g) : 628 – 634 | Mixing ratio (Parts by weight) : 24

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 5 – 15 | Pot life @ 25oC (hours) : 7 – 9 | Mixing ratio (Parts by weight) : 32

2017 marks the 70th anniversary of Atul Ltd. The history of the Company is closely linked to that of independent India: both started their journey in 1947 and endeavour to consistently improve over the years. In light of this, Polymers Retail has rolled out a pan India retailer scheme ‘Bond 70’ on select Lapox, Polygrip and Lacare products for the period of July – October 2017.

The objective of this initiative is to encourage and motivate retailers as they continue to enjoy the positive impact of GST implementation. We express our gratitude for their continued support and patronage to our brands. To avail the benefits of this scheme, please write to support_polymers@atul.co.in or call on (+91) 96193 73700.

Polymers Retail is launching a new range of maintenance products under the brand Lacare for automobile, industrial and household applications.

The upcoming product portfolio for this maintenance range is as follows:

|

Generic name |

Application |

|

Multi-purpose maintenance spray |

|

|

Channel spray |

|

Polymers Retail had a pilot launch of its retail module from April-June 2017 in Valsad, Pardi and Udwada. While it has been challenging for the Business to move from a no presence zone to a significant presence zone, the experience has been a great motivation.

A summary of the post launch outcomes is as follows:

We are also launching this model in other towns | cities of the country during 2017-18.

Polymers Performance Materials participated in ICERP 2017 in Mumbai. The exhibition was held on 10 – 12 January 2017. It gave us an opportunity to personally meet and discuss with the various personnel and decision makers of composites industry.

Atul Ltd received a certificate of merit for its greening the desert project by Flame Awards Asia, 2016

These fresh Barhee dates are from Atul’s farms in the beautiful Thar desert in Rajasthan and farmer fields in various parts of India, cultivated with Atul’s tissue culture raised date palms.

Colors Business launched an innovative mobile application for effective customer service and was conferred with the Customer Excellence award.

Dr GVG Rao, President, Colors Business, inaugurated new machinery at the Technical Services (TS) laboratory, Atul. The TS laboratory focuses on customer support activities, particularly textile dyeing and printing application techniques.

A representative from Colors Business participated in and conducted a technical seminar on ‘Selection, Evaluation, Application and Disposal of Dyes and Chemicals’ in Ethiopia. The seminar was organised by the Ethiopian Textile Industry Development Institute in twinning partnership with the Institute of Chemical Technology, India on April 21-22, 2017.

AkzoNobel y Atul han anunciado su intención de invertir conjuntamente en la producción de ácido monocloroacético (ACM) en la India. Esto incluirá el establecimiento de una planta de MCA de clase mundial en la primera planta de fabricación de Atul situada en Valsad (Gujarat). Cada socio tendrá una participación del 50 por ciento.

Esta asociación se basará en el estatus que Atul tiene como proveedor líder mundial de 2,4-D, un herbicida que utiliza el MCA como materia prima clave, y en la posición líder mundial que AkzoNobel tiene en el mercado del MCA, con plantas en los Países Bajos, China, Japón y los EE.UU. El MCA es un elemento esencial en la industria química y se utiliza en una amplia variedad de productos químicos.

La asociación utilizará el cloro y el hidrógeno fabricados por Atul para producir MCA, aprovechando la infraestructura existente que tiene Atul y la principal tecnología de hidrogenación ecológica suministrada por AkzoNobel. La planta producirá suficiente MCA para satisfacer el requerimiento cautivo de Atul; AkzoNobel comercializará el resto, principalmente en la India.

Con ocasión de Ambedkar Jayanti, el Primer Ministro Narendra Modi, bajo la dirección de Digi Dhan Vyapar Yojana de Niti Aayog, declaró a Atul Ltd., municipio de Valsad, como uno de los setenta y cinco “municipios sin dinero en efectivo” de la India, ya que más del 75% de los pagos se procesaban en formato digital en lugar de en efectivo. Los municipios seleccionados para la puesta en marcha han sido objeto de una evaluación independiente por terceros por parte de Price Waterhouse Coopers (PWC) y sólo se incluyen en esta lista los municipios que han informado de que más del 80% del número total de transacciones en el municipio se han realizado a través de medios de pago digitales durante el período de examen.

Estos dátiles Barhee frescos proceden de las granjas de Atul en el hermoso desierto de Thar, en Rajastán, y de campos de cultivo en varias partes de la India, cultivados con palmeras datileras de cultivo de tejidos de Atul.

En 2016-17, la Fundación Atul organizó campamentos de oftalmología y otorrinolaringología que beneficiaron a 3103 pacientes en 10 pueblos, 129 fueron operados de cataratas y 551 recibieron gafas.

A bio-stimulant derived from seaweed extract (Ascophyllum nodusum). The product is used as a plant growth stimulant, enhancing plant vigour at critical stages and improving crop productivity.

A silicone based surfactant used as a tank mix with and herbicides, insecticides and fungicides to improve its bio-efficacy.

A selective pre-emergence herbicide used to control most grasses and some broad-leaved weeds in various crops.

A selective pre-emergence herbicide used to control most grasses and some broad-leaved weeds in various crops.

A selective pre and early post-emergence herbicide of the Triazine group used to control a wide range of grasses and broad-leaved weeds in maize and sugarcane.

A broad spectrum systemic post-emergence herbicide used to control grassy weeds such as Echinochloa spp, sedges and broad-leaved weeds in paddy.

A selective, pre-emergence herbicide used to control most grasses and some broad-leaved weeds in transplanted paddy.

A non-selective, post-emergence contact herbicide used to control annual grasses and broad-leaved weeds in tea, row crops and non-crop areas.

A systemic insecticide with protective and curative action used to control blast in paddy.

A sulphur based fertiliser for soil application used to overcome sulphur deficiencies and nutrition stress in plants and the soil.

An inorganic contact fungicide with protective action and acaricidal activity. The product is recommended for controlling powdery mildews in various crops.

A broad spectrum systemic fungicide of the Benzimidazole group used to control a range of diseases in various crops, with its protective and curative action.

A broad spectrum contact and protective fungicide and bactericide used to control wide range of fungal diseases in various crops.

A systemic insecticide of the Neonicotinoid and Phenylpyrazole group with contact and stomach action. The product is used to control chewing and sucking insect pests.

A broad spectrum insecticide and acaricide of the Organophosphorus group used to control a range of chewing and sucking insects in various crops.

A broad spectrum insecticide | miticide of the Synthetic pyrethroids group with contact and stomach action. The product is effective against a broad range of lepidopteran pests, sucking pests, mites and termites in various crops.

A non-systemic insecticide of Organophosphorus and Synthetic pyrethroids group with contact and stomach action. The product is used to control chewing and sucking insect pests.

One-component, solvent free, nearly instant setting adhesive. The product is ideal for applications such as bonding of marble, glass, metal, plastic, wood, sun board and flex and filling gaps in PVC doors. Lapox Ultraquick is available in the pack size of 20 g.

A systemic fungicide that is used to control scab in apple, tikka leaf spot in groundnut, powdery mildew in mango and blast and sheath blight in rice.

A systemic fungicide of the Triazole group used to control fungal diseases. The product finds an application in wood preservation.

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 25 – 35

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : Thixotropic | Pot life @ 25oC (minutes) : 3 – 7

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 200 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) oC : 105 – 115

Mixing ratio (Parts by weight) : 100 : 40 | Mix viscosity @ 25oC (mPa s) : Thixotropic | Pot life @ 25oC (minutes) : 35 – 45

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 100 – 110

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 6,000 – 8,000 | Pot life @ 25oC (minutes) : 15 – 300

Mixing ratio (Parts by weight) : 100 : 65 | Mix viscosity @ 25oC (mPa s) : 8,000 – 10,000 | Pot life @ 25oC (minutes) : 15 – 330

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 43 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 30 – 35

Mixing ratio (Parts by weight) : 100 : 55 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 45 – 60

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : 35 – 330

Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 25 – 35

Mix viscosity @ 25oC (mPa s) : 600 – 1,000 | Pot life @ 25oC (minutes) : 130 – 150

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,500 – 4,500 | Pot life @ 25oC (minutes) : 110 – 130

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,500 | Pot life @ 25oC (minutes) : 60 – 80

Mixing ratio (Parts by weight) : 100 : 66 | Mix viscosity @ 25oC (mPa s) : 4,500 – 5,500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 50,000 – 1,00,000 | Pot life @ 25oC (minutes) : 35 – 50

Mixing ratio (Parts by weight) : 100 : 80 | Mix viscosity @ 25oC (mPa s) : 75,000 – 1,25,000 | Pot life @ 25oC (minutes) : 8 – 10

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 2,500 – 3,000 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 190 – 220

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 120 – 180 | Glass transition temperature (Tg) (oC) : 130 – 140

Mixing ratio (Parts by weight) : 100 : 20 | Mix viscosity @ 25oC (mPa s) : Paste (colourless) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 95 – 115

Mixing ratio (Parts by weight) : 100 : 10 | Mix viscosity @ 25oC (mPa s) : Paste (blue) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 6 | Mix viscosity @ 25oC (mPa s) : Paste (grey) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 85 – 95

Mixing ratio (Parts by weight) : 100 : 14 | Mix viscosity @ 25oC (mPa s) : Paste (white) | Pot life @ 25oC (minutes) : 25 – 30 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 38 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 110 – 160 | Glass transition temperature (Tg) (oC) : 115 – 130

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 111,000 – 13,000

A cost effective substitute for cresylic acid and phenol.

An economical trichromatic navy dye with good dischargeability. The product is used to develop medium to dark shades.

A deep red dye used for scarlet, dark red, brown and burgundy shades.

A red dye with high tinctorial strength and excellent build-up properties. The product is used to develop medium to dark shades.

A golden yellow dye with high tinctorial strength used to develop deep shades with good all round fastness properties.

A basic trichromatic golden yellow dye with good dischargeability.

A blue dye with good light fastness properties used for pale to medium shades.

A red dye with good light fastness properties used for pale to medium shades.

A yellow dye with good light fastness properties used for pale to medium shades.

An economical navy dye with good build-up properties.

A black dye used to develop black to grey shades. The product has good light fastness properties.

A turquoise dye with good build-up properties.

A turquoise dye with good build-up properties.

A brilliant reddish blue dye used to develop bright royal blue shades.

A trichromatic blue dye with good fastness properties. The product has good dischargeability.

A bright violet dye used for various shades of violet.

An economical bluish red dye used for medium and dark shades.

An economical trichromatic red dye with high tinctorial strength.

A bright orange dye used for orange and scarlet shades.

An economical golden yellow dye used in trichromatic combinations.

A bright yellow dye used in tertiary combinations with good light fastness properties.

A yellow dye with all round fastness properties.

An ideal grey component with excellent performance in Exhaust and Continuous dyeing applications by Soft flow and Pad Dry Pad steam techniques. The product has good all round fastness properties. It is available in Microperle and Micro disperse varieties.

A navy dye with excellent build-up properties used for coloration of workwear and institutional wear. The product is used in combination with Yellow 3R and Jade Green XBN for Exhaust application. It shows minimum shade change when used with flame retardants. The product is available in Microperle and Micro disperse varieties.

A systemic fungicide with protective and curative action used to control broad spectrum fungal diseases in various field crops and fruits.

A selective and systemic post-emergence herbicide readily absorbed by leaves. The product is used to control annual and perennial broad-leaved weeds in a range of crops.

A high purity grade of para Cresol for niche applications.

A starting ingredient in most versatile phenolic group antioxidants.

A naturally sourced aroma ingredient with a musk-like profile.

A key ingredient in specialty fragrance formulations.

An intermediate widely used by the Pharmaceuticals and Crop Protection Chemicals industry.

An aroma ingredient with sweet, floral, fennel and basil-like, mildly fruity odour. The product finds a major application in oral care products, flavours and fragrances.

A key building block for Dextromethorphan, a widely used formulation to treat cough and cold.

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 600 – 1,000 | Pot life @ 25oC (minutes) : 130 – 150

Mixing ratio (Parts by weight) : 100 : 66 | Mix viscosity @ 25oC (mPa s) : 4,500 – 5,500 | Pot life @ 25oC (minutes) : 40 – 50

Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 7,000 – 11,000 | Amine value (mg KOH/g) : 400 – 450 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight) : 50

Type of system : Pre-filled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 26 | Glass transition temperature (Tg) (oC) : 70 – 80 | Thermal class : F

Type of system : Pre-filled | Nature : Cold cure / Indoor | Mixing ratio (Parts by weight) : 100 : 25 | Glass transition temperature (Tg) (oC) : 60 – 70 | Thermal class : B

Type of system : Unfilled | Nature : Hot cure Indoor | Voltage class : MV / HV | Mixing ratio (parts by weight) : 100 : 15 | Glass transition temperature (Tg) (oC) : 80 – 90 | Thermal class : F

Appearance : Yellow liquid | Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 1,000 – 2,500 | Amine value (Eq/kg) : 8.00 – 9.00 | Mixing ratio (Parts by weight) : 34

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (Parts by weight) : 100 : 100 : 0.0 – 0.2 | Glass transition temperature (Tg) (oC) : 90 – 100 | Thermal class : F

Colour (Gardner) : Max 10 | Epoxy value (Eq/kg) : 2.20 – 2.60 | Viscosity @ 25oC (mPa s) : 20 – 50 | HyCl (%) : Max 1.00

Colour (Gardner) : Max 13 | Epoxy value (Eq/kg) : 1.80 – 2.40 | Viscosity @ 25oC (mPa s) : 40 – 70 | HyCl (%) : Max 1.00

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.10 – 4.50 | Viscosity @ 25oC (mPa s) : 20 – 35 | HyCl (%) : Max 0.20

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.90 – 6.30 | Viscosity @ 25oC (mPa s) : 6 – 8 | HyCl (%) : Max 0.20

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.30 – 6.00 | Viscosity @ 25oC (mPa s) : 6 – 8 | HyCl (%) : Max 0.20

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (Parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoo | Mixing ratio (parts by weight) : 100 : 30 | Glass transition temperature (Tg) (oC) : 115 – 130 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio (parts by weight) : 100 : 25 | Glass transition temperature (Tg) (oC) : 122 – 132 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC) : 90 – 105 | Thermal class : H

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC): 105 – 125 | Thermal class : H

Type of system : Unfilled | Nature : Hot cure / Indoor | Mixing ratio : 100 : 100 : 0.5 – 1.5 : 0 – 20 | Glass transition temperature (Tg) (oC): 85 – 95 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 80 | Glass transition temperature (Tg) (oC) : 75 – 85 | Thermal class : F

Colour (Gardner) : Max 6 | Epoxy value (Eq/kg) : 1.54 – 2.00 | Viscosity @ 25oC (mPa s) : 250 – 500

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 80 : 0.5 – 2.0 | Glass transition temperature (Tg) (oC) : 75 – 85 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio (Parts by weight) : 100 : 90 | Glass transition temperature (Tg) (oC): 100 – 110 | Thermal class : F

Type of system : Unfilled | Nature : Hot cure / Outdoor | Mixing ratio : 100 : 90 : 0.5 – 2.0 | Mix viscosity : 1,000/80 | Glass transition temperature (Tg) (oC): 100 – 110 | Thermal class : F

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 7.00 – 8.00 | Viscosity @ 25oC (mPa s) : 100 – 200 | HyCl (%) : Max 0.15

Type of system : Pre-filled | Nature : Hot cure Indoor | Mixing ratio (parts by weight) : 100 : 100 | Glass transition temperature (Tg) (oC) : 110 – 120 | Thermal class : H

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.90 – 8.00 | Viscosity @ 25oC (mPa s) : 12 – 18 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 2.90 – 3.20 | Viscosity @ 25oC (mPa s) : 40 – 90 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.20 – 6.80 | Viscosity @ 25oC (mPa s) : 15 – 30 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 7.00 – 7.80 | Viscosity @ 25oC (mPa s) : 10 – 22 | HyCl (%) : Max 0.15

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 6.20 – 7.30 | Viscosity @ 25oC (mPa s) : Max 2 | HyCl (%) : Max 0.10

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 3.35 – 3.70 | Viscosity @ 25oC (mPa s) : 4 – 12 | HyCl (%) : Max 0.10

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.50 – 6.30 | Viscosity @ 25oC (mPa s) : 500 – 1,100

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.10 – 5.40 | Viscosity @ 25oC (mPa s) : 860 – 960

Mixing ratio (Parts by weight) : 100 : 40 | Mix viscosity @ 25oC (mPa s) : 50,000 – 1,00,000 | Pot life @ 25oC (minutes) : 20 – 25

Mixing ratio (Parts by weight) : 100 : 65 | Mix viscosity @ 25oC (mPa s) : 8,000 – 10,000 | Pot life @ 25oC (minutes) : 15 – 330

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.40 – 5.90 | Viscosity @ 25oC (mPa s) : 1,000 – 1,500

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.40 – 5.90 | Viscosity @ 25oC (mPa s) : 1,700 – 2,500

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 18 | Mix viscosity @ 25oC (mPa s) : 600 – 700 | Pot life @ 25oC (minutes) : 15 – 25

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,000 | Pot life @ 25oC (minutes) : 100 – 110

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 6,000 – 8,000 | Pot life @ 25oC (minutes) : 15 – 300

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 5,000 – 7,000 | Pot life @ 25oC (minutes) : 25 – 35

Mixing ratio (Parts by weight) : 100 : 100 | Mix viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 45 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 30 – 40

Mixing ratio (Parts by weight) :100 : 60 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 40 – 50

Mixing ratio (Parts by weight) : 100 : 43 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 30 – 35

Mixing ratio (Parts by weight) : 100 : 55 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 45 – 60

Mixing ratio (Parts by weight) : 100 : 60 | Mix viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : 35 – 330

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,500 – 4,500 | Pot life @ 25oC (minutes) : 110 – 130

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 3,000 – 4,500 | Pot life @ 25oC (minutes) : 60 – 80

Chemistry : 3,3′-Diaminodiphenyl sulfone | Appearance : White to brownish white powder | Melting point (oC) : 167 – 175

Chemistry : 4,4′-Diaminodiphenyl sulfone Micronised | Appearance : White to off-white powder | Melting point (oC) : 176 – 180

Chemistry : 4,4′-Diaminodiphenyl sulfone Free Flow | Appearance : White to off-white powder | Melting point (oC) : 176 – 185

Chemistry : 4,4′-Diaminodiphenyl sulfone | Appearance : White to off-white powder | Melting point (oC) : 176 – 185

Chemistry : 4,4′-Diaminodiphenyl methane | Appearance : Viscous brownish liquid | Viscosity @ 60oC (mPa s) : 1,400 – 2,000

Appearance : Light yellow to brown liquid | Viscosity @ 25oC (mPa s) : 100 – 300

Chemistry : 4,4′-Diaminodicyclohexyl methane | Appearance : Colourless transparent liquid | Melting point (oC) : 35 – 37

Chemistry : 3,3’-Dimethyl-4,4’-diaminodicyclohexyl methane | Viscosity @ 25oC (mPa s) : 100 – 140

Colour (Gardner) : Yellow powder | Melting point (oC) : 155 – 158

Colour (Gardner) : Yellow solid | Viscosity @ 125oC (mPa s) : 50 – 500

Colour (Gardner) : Yellowish liquid | Solid content (%) : 74 – 76 | Viscosity @ 25oC (mPa s) : 100 – 400

Colour (Gardner) : Yellow solid | Viscosity @ 100oC (mPa s) : 1,000 – 7,000 | Softening point (oC) : 60 – 80

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 4.17 – 4.44 | Viscosity @ 85oC (mPa s) : 1,000 – 1,500

Epoxy value (Eq/kg) : 9.80 – 10.6 | Viscosity @ 25oC (mPa s) : 1,500 – 4,800

Epoxy value (Eq/kg) : 9.10 – 9.80 | Viscosity @ 25oC (mPa s) : 7,000 – 13,000

Epoxy value (Eq/kg) : 9.40 – 10.50 | Viscosity @ 25oC (mPa s) : 550 – 850

Epoxy value (Eq/kg) : 8.70 – 9.50 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000

Colour (Gardner) : Max 13 | Epoxy value (Eq/kg) : 5.88 – 6.66 | Viscosity @ 150oC (mPa s) : 30 – 55

Colour (Gardner) : Max 7 | Epoxy value (Eq/kg) : 7.52 – 8.47 | Viscosity @ 25oC (mPa s) : 7,000 – 12,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 8.55 – 9.00 | Viscosity @ 50oC (mPa s) : 3,000 – 6,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 7,000-19,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 17,000-19,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 13,000-15,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 10,000 – 12,000

Colour (Gardner) : Max 12 | Epoxy value (Eq/kg) : 7.46 – 8.55 | Viscosity @ 50oC (mPa s) : 7,000 – 11,000

Colour (Gardner) : Max 4 | Epoxy value (Eq/kg) : 5.12 – 6.10 | Viscosity @ 50oC (mPa s) : 100 – 350

Colour (Gardner) : Max 3 | Epoxy value (Eq/kg) : 5.59 – 5.81 | Viscosity @ 52oC (mPa s) : 1,100 – 1,700

Colour (Gardner) : Max 16 | Epoxy value (Eq/kg) : 6.50 – 7.50 | Viscosity @ 50oC (mPa s) : 1,000 – 2,500 | Hycl : Max 0.20

Colour (APHA) : Max 50 | Epoxy value (Eq/kg) : 5.71 – 5.95 | Viscosity @ 25oC (mPa s) : 4,000 – 5,000

Colour (Gardner) : Max 1 | Epoxy value (Eq/kg) : 5.26 – 5.55 | Viscosity @ 25oC (mPa s) : 9,000 – 12,000

Epoxy value (Eq/kg) : 0.53 – 0.59 | Viscosity @ 25oC (mPa s) : 1,800 – 2,600 | Softening point (oC) : 110 – 120

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 15,000 – 35,000 | Amine value (mg KOH/g) : 290 – 325 | Pot life @ 25oC (minutes) : 40 – 85 | Mixing ratio (Parts by weight) : 70 | Thin film set time (8 mils) (hours) : 3 – 4

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 2,000 – 4,000 | Amine value (mg KOH/g) : 490 – 550 | Pot life @ 25oC (minutes) : 30 – 55 | Mixing ratio (Parts by weight) : 40 | Thin film set time (8 mils) (hours) : 3 – 4

Colour (Gardner) : Max 15 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000 | Amine value (mg KOH/g) : 300 – 350 | Pot life @ 25oC (minutes) : 50 – 65 | Mixing ratio (Parts by weight) : 67 | Thin film set time (8 mils) (hours) : 4 – 5

Colour (Gardner) : Max 3 | Viscosity @ 25oC (mPa s) : 40 – 60 | Amine value (mg KOH/g) : 320 – 340 | Pot life @ 25oC (minutes) : 25 – 40 | Mixing ratio (Parts by weight) : 48

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 10 – 20 | Pot life @ 25oC (minutes) : 90 – 120 | Mixing ratio (Parts by weight) : 23

Colour : Max 2 | Viscosity @ 25oC (mPa s) : 1,500 – 2,000 | Amine value (Eq/kg) : 165 – 210 | Pot life @ 25oC (hours) : 4 – 6 | Mixing ratio (Parts by weight) : 30 (with resin P-101)

Colour (Gardner) : Clear liquid | Viscosity @ 25oC (mPa s) : 850 – 1,200 | Mixing ratio (Parts by weight) : 100 (with resin ARL-148)

Colour (Gardner) : Black | Viscosity @ 25oC (mPa s) : 3,000 – 6,000 | Pot life @ 25oC (minutes) : Min 20 | Mixing ratio (Parts by weight) : 100 (with resin ARB – 28)

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 2,900 – 3,600 | Amine value (mg KOH/g) : 398 – 415 | Pot life @ 25oC (minutes) : 15 – 30 | Mixing ratio (Parts by weight) : 35

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 200 – 300 | Amine value (Eq/kg) : 17.00 – 17.80 | Pot life @ 25oC (minutes) : 25 – 35 | Mixing ratio (Parts by weight) : 18

Colour (Gardner) : Max 5 | Viscosity @ 25oC (mPa s) : Max 10 | Pot life @ 25oC (minutes) : 20 – 25 | Mixing ratio (Parts by weight) : 10 – 12

Colour (Gardner) : Max 3 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight) : 10 – 12

Colour (Gardner) : Max 5 | Viscosity @ 25oC (mPa s) : 100 – 550 | Amine value (mg KOH/g) : 500 – 1,000 | Pot life @ 25oC (minutes) : 5 – 30 | Mixing ratio (Parts by weight) : 18 – 25

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 500 – 1,000 | Amine value (mg KOH/g) : 650 – 750 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight) : 25

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 5 – 10 | Amine value (mg KOH/g) : 680 – 720 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight) : 21

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 30 – 100 | Amine value (mg KOH/g) : 290 – 320 | Pot life @ 25oC (minutes) : 100 – 125 | Mixing ratio (Parts by weight) : 40

Colour (Gardner) : Max 4 | Viscosity @ 25oC (mPa s) : 50 – 60 | Pot life @ 25oC (minutes) : 35 – 50 | Mixing ratio (Parts by weight) : 15

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 5,000 – 7,500 | Amine value (Eq/kg) : 4.40 – 5.10 | Mixing ratio (Parts by weight) : 60

Mixing ratio (Parts by weight) : 100 : 15 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : 85 – 95 | Glass transition temperature (Tg) (oC) : 95 – 105

Mixing ratio (Parts by weight) : 100 : 15 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : 20 – 25 | Glass transition temperature (Tg) (oC) : 95 – 105

Colour (APHA) : Max 100 | Epoxy value (Eq/kg) : 4.16 – 4.54 | Viscosity @ 25oC (mPa s) : 2,000 – 4,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 6.00 – 6.40 | Viscosity @ 25oC (mPa s) : 1,200 – 1,600

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.30 | Viscosity @ 25oC (mPa s) : 5,000 – 7,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.10 | Viscosity @ 25oC (mPa s) : 3,300 – 4,100

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.80 – 6.10 | Viscosity @ 25oC (mPa s) : 2,000 – 3,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 5.70 – 6.30 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000

Epoxy value (Eq/kg) : 1.07 – 1.16 | Viscosity @ 25oC (mPa s) : 620 – 900 | Softening point (oC) : 100 – 110

Epoxy value (Eq/kg) : 1.25 – 1.40 | Viscosity @ 25oC (mPa s) : 500 – 700 | Softening point (oC) : 95 – 101

Mixing ratio (Parts by weight) : 100 : 3-6 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 165 – 180

Mixing ratio (Parts by weight) : 100 : 32-40 : 1-3 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 170 – 185

Mixing ratio (Parts by weight) : 100 : 64 : 1-3 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 34 | Mix viscosity @ 25oC (mPa s) : 3,500 – 5,000 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) oC : 145 – 155

Mixing ratio (Parts by weight) : 100 : 100 : 1-3 | Mix viscosity @ 25oC (mPa s) : 400 – 700 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 95 – 105

Mixing ratio (Parts by weight) : 100 : 27 | Mix viscosity @ 50oC (mPa s) : 3,000 – 5,000 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 150 – 160

Mixing ratio (Parts by weight) : 100 : 95 : 0.5-2.0 | Mix viscosity @ 25oC (mPa s) : 1,900 – 2,100 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 165 – 185

Mixing ratio (Parts by weight) : 100 : 90 | Mix viscosity @ 25oC (mPa s) : 300 – 600 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 115 – 125

Mixing ratio (Parts by weight) : 100 : 90 : 1-3 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 115 – 130

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 200 – 500 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 105 – 115

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 400 – 700 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 1,200 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 1,200 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) oC : 90 – 105

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 800 | Pot life @ 25oC (minutes) : 7 – 9 hr | Glass transition temperature (Tg) oC : 85 – 95

Mixing ratio (Parts by weight) : 100 : 50 | Mix viscosity @ 25oC (mPa s) : 1,200 – 1,500 | Pot life @ 25oC (minutes) : 120 – 150 | Glass transition temperature (Tg) oC : 55 – 65

Mixing ratio (Parts by weight) : 100:32 | Mix viscosity @ 25oC (mPa s) : 600 – 800 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 20 | Mix viscosity @ 25oC (mPa s) : Paste (colourless) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 95 – 115

Mixing ratio (Parts by weight) : 100 : 10 | Mix viscosity @ 25oC (mPa s) : Paste (blue) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 14 | Mix viscosity @ 25oC (mPa s) : Paste (white) | Pot life @ 25oC (minutes) : 25 – 30 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 24 | Mix viscosity @ 25oC (mPa s) : 250 – 400 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 125 – 135

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 3.57 – 4.45 | Viscosity @ 25oC (mPa s) : 450 – 800

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 800 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 75 – 85

Epoxy value (Eq/kg) : 1.08 – 1.18 | Viscosity @ 25oC (mPa s) : 430 – 550 | Softening point (oC) : 90 – 100

Epoxy value (Eq/kg) : 1.23 – 1.33 | Viscosity @ 25oC (mPa s) : 480 – 580 | Softening point (oC) : 80 – 90

Epoxy value (Eq/kg) : 1.33 – 1.40 | Viscosity @ 25oC (mPa s) : 500 – 600 | Softening point (oC) : 95 – 101

Mixing ratio (Parts by weight) : 100 : 5 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 15 : 2 | Pot life @ 25oC (hours) : > 8 | Glass transition temperature (Tg) (oC) : 155 – 165

Mixing ratio (Parts by weight) : 100 : 32 : 1-3 | Pot life @ 25oC (weeks) : 2 – 3 | Glass transition temperature (Tg) (oC) : 130 – 140

Mixing ratio (Parts by weight) : 100 : 23 : 0.5-3.0 | Pot life @ 25oC (weeks) : 2 – 3 | Glass transition temperature (Tg) (oC) : 130 – 140

Epoxy value (Eq/kg) : 1.25 – 1.35 | Viscosity @ 150oC (mPa s) : 4,500 – 6,500 | Glass transition temperature (Tg) (oC) : 55

Mixing ratio (Parts by weight) : 100 : 35 : 1-3 | Pot life @ 25oC (weeks) : 6 – 8 weeks | Glass transition temperature (Tg) (oC) : 150 – 160

Epoxy value (Eq/kg) : 1.42 – 1.53 | Viscosity @ 25oC (mPa s) : 375 – 475 | Softening point (oC) : 80 – 90

Appearance : Clear yellow liquid | Colour (Gardner) : Max 6 | Viscosity @ 25oC (mPa s) : 150 – 300 | Amine value (mg KOH/g) : 580 – 635

Mixing ratio (Parts by weight) : 100 : 27 | Pot life @ 25oC (hours) : > 4 | Glass transition temperature (Tg) (oC) : 150 – 160

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 300 – 600 | Amine value (mg KOH/g) : 260 – 310 | Pot life @ 25oC (minutes) : 40 – 50 | Mixing ratio (Parts by weight) : 50

Colour (Gardner) : Max 2 | Viscosity @ 25oC (mPa s) : 150 – 300 | Amine value (mg KOH/g) : 335 – 375 | Pot life @ 25oC (minutes) : 25 – 40 | Mixing ratio (Parts by weight) : 40

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 50 – 150 | Amine value (mg KOH/g) : 340 – 390 | Pot life @ 25oC (minutes) : 30 – 40 | Mixing ratio (Parts by weight) : 45

Mixing ratio (Parts by weight) : 100 : 85 : 1-3 | Mix viscosity @ 25oC (mPa s) : 600 – 900 | Pot life @ 25oC (minutes) : > 8 | Glass transition temperature (Tg) (oC) : 130 – 140

Colour (Gardner) : Max 2 | Amine value (mg KOH/g) : 330 – 360 | Pot life @ 25oC (minutes) : 20 – 50 | Mixing ratio (Parts by weight) : 45

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 1,500 – 2,500 | Pot life @ 25oC (minutes) : 300 – 350 | Glass transition temperature (Tg) (oC) : 130 – 140

Colour (Gardner) : Max 1 | Viscosity @ 25oC (mPa s) : 400 – 600 | Amine value (mg KOH/g) : 250 – 300 | Pot life @ 25oC (minutes) : 30 – 45 | Mixing ratio (Parts by weight) : 60

Colour (Gardner) : Max 12 | Viscosity @ 25oC (mPa s) : 1,000 – 2,000 | Amine value (mg KOH/g) : 280 – 300 | Pot life @ 25oC (minutes) : 46 – 65 |

Mixing ratio (Parts by weight) : 60 (with resin B-47)

Colour (Gardner) : Max 10 | Viscosity @ 25oC (mPa s) : 2,500 – 5,500 | Amine value (mg KOH/g) : 202 – 225 | Pot life @ 25oC (minutes) : 80 – 100 | Mixing ratio (Parts by weight) : 100

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 8 | Viscosity @ 25oC (mPa s) : 500 – 1,000 | Amine value (mg KOH/g) : 425 – 450 | Pot life @ 25oC (minutes) : 120 – 130 | Mixing ratio (Parts by weight) : 50

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 9 | Viscosity @ 25oC (mPa s) : 12,000 – 18,000 | Amine value (mg KOH/g) : 350 – 400 | Pot life @ 25oC (minutes) : 60 – 80 | Mixing ratio (Parts by weight) : 50 – 55

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Colour (Gardner) : Max 9 | Viscosity @ 25oC (mPa s) : 45,000 – 60,000 | Amine value (mg KOH/g) : 290 – 320 | Pot life @ 25oC (minutes) : 110 – 130 | Mixing ratio (Parts by weight) : 55 – 65

Mixing ratio (Parts by weight) : 100 : 6 | Mix viscosity @ 25oC (mPa s) : Paste (grey) | Pot life @ 25oC (minutes) : 15 – 20 | Glass transition temperature (Tg) (oC) : 85 – 95

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 2,500 – 3,000 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 190 – 220

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 100 – 110

Colour (Gardner) : Max 9 | Viscosity @ 40oC (mPa s) : 50,000 – 75,000 | Amine value (mg KOH/g) : 210 – 230 | Mixing ratio (Parts by weight) : 100 – 125

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 700 – 900 | Amine value (Eq/kg) : 4.70 – 5.00 | Mixing ratio (Parts by weight) : 60

Mixing ratio (Parts by weight) : 100 : 30 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 120 – 180 | Glass transition temperature (Tg) (oC) : 130 – 140

Appearance : Dark brown liquid | Colour (Gardner) : Max 16 | Viscosity @ 25oC (mPa s) : 15,000 – 21,000 | Amine value (Eq/kg) : 4.40 – 4.80 | Mixing ratio (Parts by weight) : 60

Appearance : Brown liquid | Colour (Gardner) : Max 13 | Viscosity @ 25oC (mPa s) : 3,800 – 5,800 | Amine value (Eq/kg) : 4.70 – 5.10 | Mixing ratio (Parts by weight) : 60

Epoxy value (Eq/kg) : Max 0.08 | Viscosity @ 25oC (mPa s) : 2,000 – 5,000 | Non-volatile content (%) : 49 – 51 (160oC/2h)

Epoxy value (Eq/kg) : 1.80 – 2.20 | Viscosity @ 25oC (mPa s) : 14,000 – 20,000 | Non-volatile content (%) : 74 – 76 (150oC/2h)

Epoxy value (Eq/kg) : 1.90 – 2.20 | Viscosity @ 25oC (mPa s) : 9,000 – 13,000 | Non-volatile content (%) : 74 – 76 (150oC/2h)

Epoxy value (Eq/kg) : 3.10 – 3.40 | Viscosity @ 25oC (mPa s) : 600 – 850 | Non-volatile content (%) : 79 – 81 (150oC/1h)

Colour (Gardner) : Max 3 | Epoxy value (Eq/kg) : 5.50 – 6.00 | Viscosity @ 25oC (mPa s) : 25,000 – 35,000

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.40 – 4.60 | Viscosity @ 25oC (mPa s) : 800 – 1,500 | Non-volatile content (%) :79 – 81 (150oC/1h)

Colour (Gardner) : Max 2 | Epoxy value (Eq/kg) : 4.40 – 4.60 | Viscosity @ 25oC (mPa s) : 150 – 350 | Non-volatile content (%): 79 – 81 (105oC/2h)

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 500 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 700 – 1200 | Pot life @ 25oC (minutes) : 8 – 14 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 22 | Mix viscosity @ 25oC (mPa s) : 800 – 1,200 | Pot life @ 25oC (minutes) : 90 – 120 | Glass transition temperature (Tg) (oC) : 140 – 155

Mixing ratio (Parts by weight) : 100 : 42 | Mix viscosity @ 25oC (mPa s) : 300 – 500 | Pot life @ 25oC (minutes) : 600 – 700 | Glass transition temperature (Tg) (oC) : 170 – 200

Mixing ratio (Parts by weight) : 100 : 35 | Mix viscosity @ 25oC (mPa s) : 400 – 600 | Pot life @ 25oC (minutes) : 300 – 350 | Glass transition temperature (Tg) (oC) : 110 – 120

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 350 – 450 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 200 – 300 | Pot life @ 25oC (minutes) : 300 – 380 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 80 – 100 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 300 – 700 | Pot life @ 25oC (minutes) : 50 – 60 | Glass transition temperature (Tg) (oC) : 75 – 85

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 25 – 35 | Glass transition temperature (Tg) (oC) : 80 – 90

Mixing ratio (Parts by weight) : 100 : 32 | Mix viscosity @ 25oC (mPa s) : 600 – 750 | Pot life @ 25oC (minutes) : 14 – 20 | Glass transition temperature (Tg) (oC) : 80 – 90